PE Film Market Analysis: Geomembrane Liners

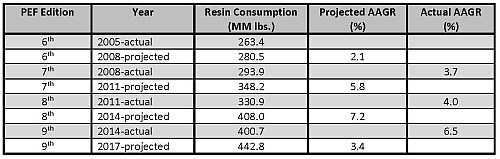

Market to average 3.4% growth over the next two years.

In 2014, approximately 400.7 million lb of PE resins were consumed in the production of geomembrane lining systems. With an average annual growth rate of 3.4%, total PE resin consumption for this market is expected to reach 442.8 million lb by 2017.

These are among the conclusions of the most recent study of the PE Film market conducted by Mastio & Co., St. Joseph, Mo.

According to Mastio, geomembrane liners are typically divided into four major groups :

Waste containment: Waste containment applications include hazardous, industrial, and municipal waste. Hazardous landfills, landfill caps, chemical ponds, wastewater lagoons, and solid waste landfills are the most common applications for waste containment geomembrane lining systems. Toxic pollutants in household garbage come from chemicals in cleaning products, paints, oils, insecticides, solvents and other products. The PE liner layer protects surrounding soil and groundwater from toxic chemicals.

Liquid containment: Liquid containment applications include lining systems for aquaculture markets, such as potable water, recreational containment, water conveyance, earth dams, and lining tanks and ponds. The liquid containment market is growing steadily due to international reconstruction of water reservoirs requiring lining systems and floating covers.

Mining applications: Mining, also known as heap leach mining, utilizes synthetic liners to contain chemicals used in extracting minerals such as gold, silver, and copper from ores. The leaching process requires a liner to contain the ore which has been sprayed with cyanide or other chemicals to extract the minerals. The chemical extract is then drained into a holding pond where the minerals are removed from the solution by an electrolytic process. Blast hole liners are used for lining blast holes in the mining industry. As the liner is lowered into a blast hole, the pointed shape of the lower end tends to center the liner in the hole. Upon reaching the bottom of the hole the weighted pocket sags to one side of the hole and allows later added explosive material to be received at the very bottom of the hole.

Specialty/other applications: These consist of decorative pond liners, tunnels and irrigation canals, cutoff walls, dams, vapor barriers, highway construction, and additional temporary and lightweight lining applications.

Geomembrane lining systems typically have a minimum thickness of 20 mils and a maximum of 120 mils, Mastio says. However, custom liners can range in thickness from 4 mils to 300 mils. The most common gauge for geomembrane liners is 60. Due to the thickness of this product, geomembrane liners are typically referred to as sheet rather than film.

Most geomembrane liners must be over 20-mils thick to insure longevity. Only a small portion of geomembrane liners are less than 20 mils and are recommended for specialty applications, such as water barriers for potable water and non-potable water.

Geomembrane liner dimensions vary according to the application and the gauge, states Mastio. Geomembrane liner widths range from 15 ft to 34.5 ft with a typical width of 22 to 23 ft. Liner length varies according to the gauge and weight of the liner. The dimensions of a typical 60-mil geomembrane liner are 23-ft-wide by 500-ft-long totaling an area of 11,500 ft².

Geomembrane liners are extruded and shipped in rolls, Mastio notes. Roll weights vary from 2500 lb up to 7500 lb depending upon liner dimensions and thickness. The roll weight for a typical 60-mil, 23-ft-wide by 500-ft long liner is approximately 3400 to 3900 lb, with a core weight ranging from 40 to 70 lb. Geomembrane liner rolls are shipped on flatbed trailer trucks. Rolls that are shipped overseas are transported in open or closed top containers. Typically, up to 12 full rolls can be shipped per truckload or container.

Geomembrane liners are specifically designed for prolonged exposure to elements in which they are intended. HDPE resin is the most common PE material used in the production of geomembrane liners.

MATERIAL ALTERNATIVES

According to the Mastio research, geomembrane liners are typically made from materials such as HDPE, LLDPE, PVC, chlorosulfinated PE, chlorinated PE , and PP, which are designed primarily for containment, water treatment, and protection. Several critical properties, such as flexibility, high strength, durability, puncture resistance, UV stability, and chemical resistance are expected of a high quality lining system.

TECHNOLOGY TRENDS

During 2014, the most common process utilized in the production of geomembrane liners was blown film extrusion, accounting for 72.7% of PE resin consumption. Sheet extrusion accounted for the rest,

Blown film extrusion requires very large dies to manufacture geomembrane liners, normally 86 in. dia. A roll width of 22.5-ft can be produced with a 1:1 blow-up ratio. Widths up to 48 ft. can be achieved by increasing the blow-up ratio, but the increased widths decrease the number of rolls that can be placed on a flatbed truck, increasing transportation costs.

Both monolayer and coextruded structures are produced for geomembrane liners. In 2014, multi-layer coextruded PE film accounted for 52% of the market. Usually these are two- or three-layer structures.

Related Content

Consistent Shots for Consistent Shots

An integral supplier in the effort to fast-track COVID-19 vaccine deployment, Retractable Technologies turned to Arburg and its PressurePilot technology to help deliver more than 500 million syringes during the pandemic.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More