Giving employees the time, resources to “go back to school”

Consistent production is the number one priority at any plastics processing plant, but how much do most companies do to train technicians before they hand over the keys to hugely expensive (and complicated) machines that are at the heart of production?

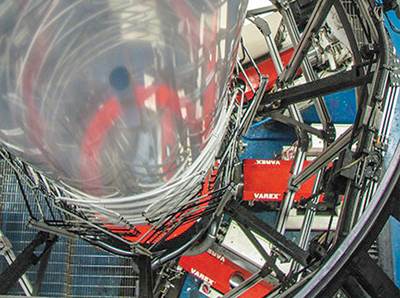

Extruder Charter NEX Films, created by the combination of Charter Films and NEX Performance Films (read the June 2014 Onsite about the company), picked up on how important training was over a decade ago as Charter Films, according to Eric Smith, general manager. Plastics processing requires consistency—same material formula run with the same machine settings and the same inspection—but that repeatability is often lacking when it comes to training.

“Historically, training was done by another operator,” Smith says, “and depending on who the trainer was and the message you received on that specific day, the consistency becomes a little bit questionable. The other thing is: how do you make sure you get the message on how to do things across to people in the correct way, because over time, things can get lost in translation between individuals.”

The University is founded

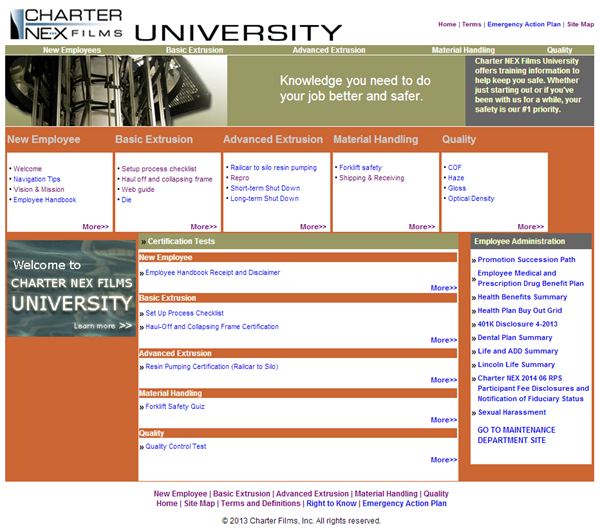

For the sake of consistency, and to make its training more regimented, then Charter Films instituted its Charter University over a decade ago. As part of the June OnSite, Jim Callari highlighted the Charter NEX University (CNU) initiative. I spoke with Smith about the program as I researched a feature on workforce development for the our upcoming September issue.

The company, which buys German-made Windmoeller & Hoelscher lines, started CNU with a focus on the high-tech machines, according to Smith.

“The idea that you’re going to take a 400-page manual and put it in front of somebody’s who come in to operate your line and train them that way just isn’t very productive,” Smith explains. Charter NEX’s solution was to break down specific components of the machine and the process and then post training modules, consisting of images, text and videos, to the company’s internal Intranet. At the end of each module, employees complete a test based on its content, to ensure the operator has seen and absorbed the lesson.

The program has evolved from integrating new workers to showing existing employees a potential career path within the company, and what knowledge they’ll need to advance down the road of promotion.

“CNU has laid out directly what employees need to do get to that next step in their job progression,” Smith says. “So it is a really a great development tool as well, in terms of saying, ‘We want our operators and our employees to grow, and here is the path they need to follow to do that.’ The sky’s the limit based on what you can do in terms of showing proficiency in developing these skills. There really was the opportunity to have people grow as quickly as they wanted to or could demonstrate.”

Living, breathing document

An overriding goal of CNU is to be continuously adapting, Smith explains, not only updating as process technology evolves, but also adding new topics, including ones outside shopfloor machinery.

“Now CNU is beyond just the training on pieces of equipment,” Smith said, noting that there are currently modules covering everything from health benefits to an employee’s 401K. “It goes beyond just the training. You’ve got a group of people who are asking, ‘What are the next topics for this living, breathing document? What is the next module that we think will be a valuable tool for the people that work in our facilities?’”

Giving employees the time, resources to learn

Another key to the program’s success: allotting time for employees to “hit the books” during their workday, with each employee provided with the time to do this development work while they’re on their shift, according to Smith.

“Employees have the ability to sit down and work through that module in the half hour or 45 minutes it takes to go through it,” Smith says, “and all of that development occurs while they’re on their shift, which shows the commitment of the company to say, ‘This is important to us, and we will provide that time for you to be able to do that while you’re here.’”

One recurring theme that came up again and again as I spoke with processors about the “skills gap” facing the U.S. manufacturing industry, was the need to look within a company’s own walls for new talent. If it’s hard to find (or pay them if you do) qualified process techs outside your company, commit to building your own in house, like Charter NEX has.

“There can be so many questions with regards to a sophisticated piece of equipment when you have somebody who really has no blown film manufacturing experience,” Smith explains “and being able to get that direct time to ask questions and have them answered—really allowing the opportunity for that development—I think that’s pretty unique in terms of a manufacturing operation.”

Related Content

Part 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreHow to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

Read MoreRead Next

Things Are Adding Up Nicely For Charter NEX Films

Since Charter Films merged with NEX Performance Films about 18 months ago, the combined operation has melded the best capabilities of each company into a single business churning out a wide scope of blown films.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More