Sheet Extruder Bixby & Bioplastics Firm Green Dot Bolster R&D Partnership

It may be safe to say by now that we can expect to see more and more ‘collaborations’ between plastics processors of a wide range of consumer goods and suppliers of bioplastics as they look for more sustainable options for their products.

It may be safe to say by now that we can expect to see more and more ‘collaborations’ between plastics processors of a wide range of consumer goods and suppliers of bioplastics as they look for more sustainable options for their products. Just last month (Processor’s Edge, PT June 2015), we reported on manufacturer of laboratory disposable products Labcon North America and its collaboration with Braskem North America to switch to the latter’s sugarcane ethanol-based HDPE for its packaging, with plans in the future to use the latter’s ‘Green’ PP for the actual components.

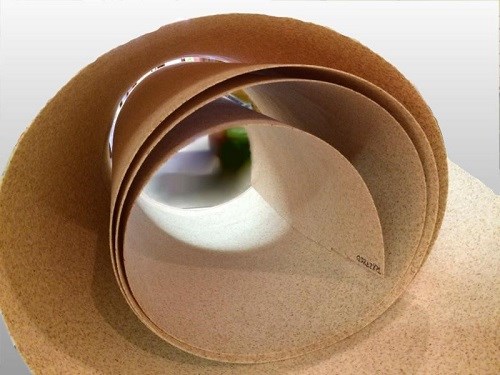

This month, we’ve have the announcement from thermoplastic sheet extruder and laminator Bixby International, Newburyport, Mass., about its R&D cooperation with bioplastics company Green Dot Holdings, Cottonwood Falls, Kansas. Bixby offers one of the industry’s broadest polymer and substrate selections and prides itself in being able to address the most challenging plastic mono- and multi-layer film and sheet applications.

Green Dot has a full line of biobased and compostable materials sold under the Terratek brand name. One example, on which we have reported, is Terratek GDH-B1 starch-based elastomer which has been used for products like cellphone cases and toys. It is also offered as an impact modifier for PLA—at 10-20% levels, it boosts PLA’s notched Izod by 100-130%, and at 30% addition, it boosts impact strength by 450%. Also cited is an exponential jump in tensile properties, particularly elongation at break.

Meanwhile, it turns out Bixby has been working with Green Dot for a couple of years. The story goes that the latter reached out to Bixby in late 2012, according to Green Dot’s CEO Mark Remmert, for one overwhelming reason: to work with Mark Gagnon, Bixby’s v.p. of R&D/product development.

Remmert praised Gagnon, noting, “Not only is he a recognized leader in plastic technology and plastics processing, but he is also that rare blend of knowledge, experience, energy, passion, and honesty. Marc never tires of explaining processes and investing his time in understanding customer needs and struggles. He is a great guy to work with.” He adds that Bixby’s product development capabilities are exceptional noting that they can go from idea, to concept, to prototype, very quickly. “The product development staff has the experience, equipment, and material know-how, to help customers turn their imagination into reality…and do it quickly.”

Several months after the two companies connected, they ran their first development prototypes for making elastomeric-coated textiles. Since then, the programs developed by the companies have focused on renewable/biodegradable products in textiles, wood-filled plastic composites, foamed extrusions, extrusion-coated natural fibers/fabrics, natural-fiber-reinforced sheet, and elastomeric film and sheet. The companies see their development cooperation as going a long way in helping generate options that have a positive impact on Green Dot’s customers, as well as the environment.

Affirming this, Gagnon notes that Bixby has been enthusiastic about its work with Green Dot because of their unique bioplastic resin technologies. “Their polymers have allowed us to explore and compete against conventional plastics with both elastomeric and rigid extruded applications whereas their biodegradability brings enhanced value to the applications of our end-users. The most exciting fact is that we have not had to sacrifice on performance—either in physical properties or processing—in order to deliver the additional benefits of a true biopolymer.”

For more about Bixby's capabilities, click to this article.

Want to find or compare materials data for different resins, grades, or suppliers? Check out Plastics Technology’s Plaspec Global materials database.

Related Content

Latest Data on Bottled Water Shows Continued Strong Growth

Bottled water’s volume surpassed soft drinks for the first time in 2016 and has done so every year since.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreRead Next

On Site: 140 Years…And Growing Stronger

Now in its fifth generation of family ownership, this sheet extruder isn’t all about output. Its focus is on creating solutions in highly customized markets that aren’t immediately associated with sheet.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More