New in PET: Injection-Compression-Stretch-Blow Molding

Continuous, rotary injection-compression molding of preforms is linked to rotary stretch-blow molding.

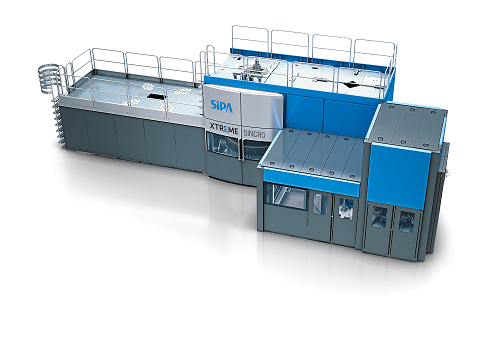

At November’s BrauBeviale show in Nuremberg, Germany, SIPA of Italy (U.S. office in Atlanta) has launched Xtreme Syncro, billed as the world’s first injection-compression-stretch-blow molding (ICSBM) system. It brings together SIPA’s Xtreme preform compression molding system with a high-speed stretch-blow unit.

As reported in our K 2013 show wrap-up last February, the Xtreme continuous, rotary injection-compression system reportedly produces preforms up to 10% lighter than any made by conventional injection molding, but without sacrificing key properties. Before now, the maximum length-to-wall-thickness ration (L/t) of a preform was little more than 45; but Xtreme technology is claimed to make an 80 L/t ratio a commercial reality.

Injection-compression simplifies thin-wall molding by having the molds slightly open when injection starts, then closing them as dosing finishes. This means lower injection pressure, lower clamp force, and less stress on the melt, which means less acetaldehyde (AA) generation and less reduction in IV.

Xtreme’s mechanical layout is similar to rotary stretch-blow machines. It is all-pneumatic, with no hydraulics. Molds are mounted in blocks of three on a high-speed carousel fed by an extruder that runs continuously. It delivers melt to dosing devices directly under the preform molds.

In the new system, preform molding is directly coupled to SIPA’s latest SFR EVO3 rotary reheat stretch-blow unit (also discussed last February), which can put out 2250 bottles/hr per cavity. The Xtreme portion alone is said to cut energy use around 10% through lower temperatures and pressures. And integration with the bottle blowing system eliminates most of the need to reheat the preforms. Conventional IR ovens are replaced by small ovens that use highly efficient induction heating directed only at areas of the preforms just below the neck. The system can also be connected directly to SIPA’s bottle filling system.

Related Content

-

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.