Spring Tips for Dryer Maintenance

The warm, humid weather really puts a strain on both the regeneration and process, so it is important that everything is in perfect working order. The time to check is now.

Now that it finally stopped raining, (maybe) and the summer months are coming up, it is time to look at some preventive maintenance for your resin dryers—they are a key component in keeping your production levels up, and your scrap rate down.

Regardless of the type of dryer you have, multiple bed, twin tower or wheel, all dryers change internally between regeneration (removing the moisture out of the drying media) and process (removing the moisture out of the resin).

The warm, humid weather really puts a strain on both the regeneration and process, so it is important that everything is in perfect working order. On the process side (side that sends dry air to the drying hopper) cracked or crushed hoses, missing hopper covers, and missing hopper door gaskets (if your drying hopper has them) are areas where the warm, humid air can infiltrate the system, loading the desiccant beds with moisture that leads to high dewpoints (which = bad parts!). Clean filters are also important as dirty filters will restrict air flow and cause extended drying times as the resin does not get up to its drying temperature.

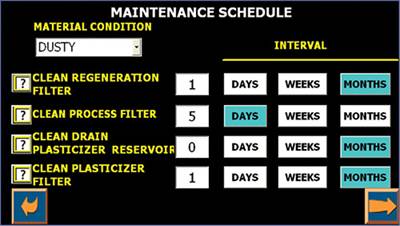

On the regeneration side (side that regenerates the desiccant beds), clean filters are a key component in providing adequate air flow to regenerate the beds quickly. Filters can not only be contaminated by dust and fines, but also by plasticizer released from the resin that condenses and coats the dryer filter—so the filter might look clean from dust, but it's not! So it's a good idea to change the filters on a regular basis. As a rule of thumb, if you are processing only virgin resins, change your filters every 6 months. If you are processing regrind or resins with a high glass content set up a schedule based on physical appearance.

If you see oil or other contaminates in the filter, or in the filter housing this is plasticizer releasing out of the resin. To trap the volatiles from contaminating your filters (and eventually your desiccant beds) your dryer will need an aftercooler and plasticizer trap. If your dryer already has a trap and cooler assembly and plasticizer is still an issue, consult your resin manufacture for the correct drying temperature, your drying temperature might be too high. Just a few degrees over the recommended drying temperature can have a major impact on how much plasticizer is released from the resin. Reduction in airflow from clogged filters also inhibit regeneration which can lead to high dewpoints and temperature spikes if your dryer does not control regeneration based on temperature.

While checking the dryer filter, also inspect the filter housing—check for missing gaskets, lid retaining fasteners etc. Check the lid itself, does it fit correctly? It is important that the lid fits the housing without leaks or gaps as these commonly removed items often get banged up over the years.

If your dryer is equipped with a return air heat exchanger or aftercooler, you should also inspect the heat exchanger for blockage. To do this remove the hoses and check the tubes for dust and other obstructions that can block/ restrict the airflow - this is particularly true for users of long glass fiber materials—these fibers often block heat exchangers and filters. Contact your dryer manufacture about a cyclone separator to protect the system if these become a continuous problem.

Resin storage is another important area. As resin is in sealed bags to keep it dry, the minute you open the bag it starts absorbing moisture. Keep bags sealed as long as possible and put any unused resin into sealed containers - resins like glass-filled nylons and some urethanes can require 16 hr dry times if left in an open environment. If your resins come in gaylords, covers are recommended to keep the dirt and moisture out.

About the Author: Jason Sears is the president of Dri-Air Industries. He earned his B.S. in Chemical Engineering from the University of Rhode Island in 1992. Much of his focus is spent on engineering new products, designing equipment for new applications, technical troubleshooting, manufacturing, and customer service. Following in the footsteps of his late father, Charlie Sears, who established Dri-Air Industries Inc. in 1974, Dr-Air focuses on customer service, hard work, and continuous improvements. He has championed the use of the Plasti-Van at the local schools and is a member of the Society of Plastics Engineers. Contact: 860-627-5110; sales@dri-air.com; dri-air.com

Related Content

Finding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read MoreCaptive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

Read MoreSoftware Helps Processors Make Better Business Decisions

NPE2024: Tracker Monitoring and Reporting Software supports ISO reporting and material validation, including PCR usage and equipment status monitoring.

Read MoreHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

Read MoreRead Next

Dri-Air Expansion Boosts Warehouse, Manufacturing Capacity

Dri-Air Industries (East Windsor, Conn.) recently completed a significant addition at its headquarters and manufacturing facility.

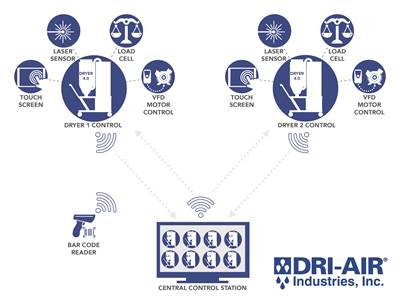

Read MoreDri-Air Readies Its Dryers for Industry 4.0 Today, and Industry 4.0 in the Future

Industry 4.0 is very much a work in progress, with key standards and protocols still in development, but that’s not stopping Dri-Air Industries from jumping into the technology.

Read MoreSavvy Processors Reveal Best Practices on Drying

The processors speak: Here’s how some smart molders and extruders tackle the vexing problem of resin drying.

Read More