Tampoprint Shined at K 2016

With its 60 years of experience in machine engineering, Tampoprint belongs among the innovators of the pad-printing industry, according to founder and chairman Wilfried Philipp.

With its 60 years of experience in machine engineering, Tampoprint belongs among the innovators of the pad-printing industry, according to founder and chairman Wilfried Philipp.

The company went to K 2016 to introduce four new concepts for the pad-printing process, which is projected to increase in demand 4-5%/yr in the coming years.

Said to be the first of its kind is the patent-pending Continuous Circular rotation pad-printing system. This new machine enables the continuous decoration of cylindrical parts, making the printing process significantly more efficient and productive. According to Tampoprint, it is well suited for a range of applications from cosmetic packaging to writing utensils to technical mass-produced articles. Better quality and high precision are claimed and multicolored printing is possible. The unit’s output is up to 15,000 parts/hr.

Another new machine concept launched and demonstrated by the company was Module One, a semi-automated modular design developed for small and medium batch sizes. The central element of Module One is formed on a base frame, which can be assembled flexibly. Module One has eight stations and can be outfitted with up to three machine satellites. Pad printing units are selected from the company’s Series Hermetic and Sealed Ink Cup E. The remaining positions can be independently outfitted; for instance, with intermediate drying, infrared drying and part recognition.

With a maximum three-color print image and a maximum diameter of 125 mm, this system is suitable for a range of applications including toys, electronic housings, and household appliances. Construction and installation are reduced through standardization of all assemblies and ancillary options, according to the company. Significantly shortened setup times are claimed.

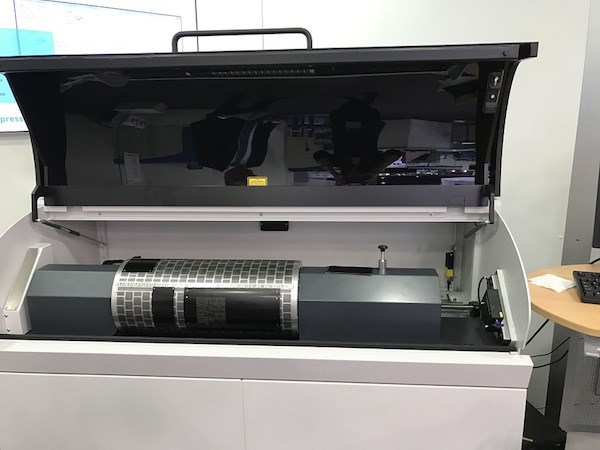

The company also showed the new variLEX 8130T pre-press laser system for graphics. It was developed by Tampoprint’s technology partner SPGPrints of Austria, a leading supplier of digital imaging technologies. This system is developed for direct engraving/ imaging black pad-printing plates—essentially replacing the conventional photopolymer plates. In combination with the black pad-printing plates, this system reportedly allows an optimal workflow which eliminates the use of any film-making (the photopolymer plate process), exposing, washing or drying.

The variLEX 8130T is also said to reduce tolerances and possible errors, which increasing quality. This system is capable of engraving high-quality line-counts, making it suitable for all pad-printing applications. SPGPrints says, it developed its laser system to image the needed relief-depth in one shot, resulting in smooth slopes, which in turn ensures an optimal ink release. Engraving time for three plates (100 x 220 mm) is 10 minutes with an engraving depth of 25-45 µm, both depending on imaging parameters and design, with up to 5080 dpi resolution claimed.

Finally, designed to work hand-in-hand with the cliché laser veriLEX 8130T, Tampoprint showcased the new “Do-It-Yourself” Intaglio laser cliché, said to deliver unrivaled pad printing results. The user creates the Intaglio laser cliché, fast and operator free, with the veriLEX 8130T. The user fastens the cliché on the magnetic drum, loads the print image on the PC and engraves. Here’s how it works: point by point the smallest cells are engraved in the Intaglio laser cliché. Each of them very precise, with different depths and widths. The pad printing ink can be precisely printed in different shades. Up to 30,000 prints in a contour sharpness can be achieved.

Related Content

Polyfuze Graphics Corp. Partners With RFID Specialists

To help customers navigate the complexities of RFID technology, Polyfuze has partnered with such companies as HID Global.

Read MoreOMV Technologies Gets New CEO

Kooper brings 33 years of experience in the industrial and consumer packaging industries to OMV--the closed-loop, turnkey, inline extrusion, thermoforming and tooling systems manufacturer.

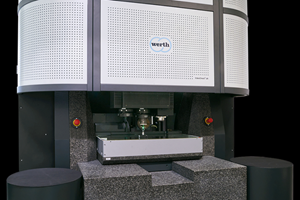

Read MoreUpgraded CT Scanning and Multi-Sensor Coordinate Measuring Machines

Werth’s TomoScope S Plus 240 systems boast more than double the measuring volume as their predecessor with almost the same size.

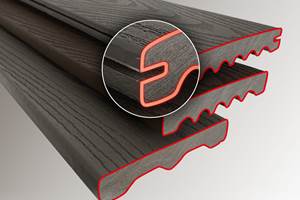

Read MoreInline Inspection System for Wood Plastic Composites

Pixargus’ ProfilControl 7 DX WoodPlasticComposites measure all dimensions and geometrics, including deep grooves.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More