Upgraded CT Scanning and Multi-Sensor Coordinate Measuring Machines

Werth’s TomoScope S Plus 240 systems boast more than double the measuring volume as their predecessor with almost the same size.

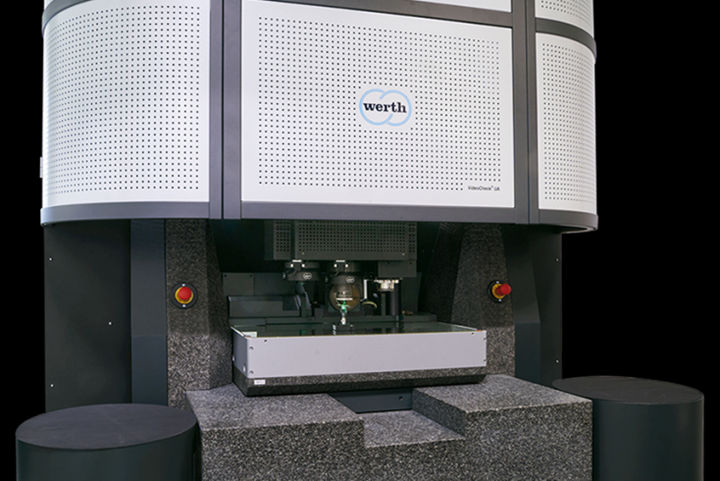

Touted as the world’s most accurate multi-sensor coordinate measuring machine is the newly upgraded TomoScope S Plus 240 from Werth Inc. The TomoScope S Plus measuring systems reportedly have more than twice the measuring volume of their predecessors with nearly the same size. With the unique specifications of MPE for E of (4 + L/75) µm and MPE for SD of (2.5 + L/100) µm, the series is also said to offer what is most likely the highest accuracy in its machine class. Key contributing factors to this high accuracy are the use of low vibration precision air bearings and solid granite construction

The modular instrument system has been expanded; the TomoScope S can now also be equipped with large detectors, for example. In addition, new operating modes such as Laminography and eccentric tomography scan “OnTheFly” are available for the TomoScope S series. Probably the world’s first sub-microfocus source in monoblock design can be used for all Werth CT machines. Long-life components are said to enable high-resolution measurements with high availability and low maintenance costs. With such a machine, the potential of highly accurate sensors can be fully exploited, according to the company. In the new accuracy-optimized design, the MPE for the VideoCheck UA has been reduced to (0.15 + L/2000) µm) option. The new machines feature improved decoupling of ambient vibrations, improved long-term temperature stability and improved measurement uncertainty for multi-sensor systems. These systems’ VideoCheck S feature up to three independent Z-axes for perfect integration of multi-sensor systems.

Machines specifications include measuring range of X 400mm (16 in.),Y 400mm (16 in.) and Z 250mm (10 in.). Footprint and specification are: depth 1665 mm (67 in.), width of 1840 mm (72 in.) and height of 2200mm (86 in.).

Related Content

-

Redesigned Laser Scanner Boasts Improved Accuracy, Resolution, Versatility, and Efficiency

Nikon Metrology’s new LC15Dx is ideal for efficient measurement and inspection of manufactured components including intricate plastic parts.

-

Robust Rotational Viscometer

Versatile viscometer line said to offer robust measurement, repeatability and reporting.

-

Tracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.