It’s a relatively simple idea: take strands of glass fiber, cut them to length and feed them into the barrel of an injection molding machine, where they mix with neat resin before the resulting compound is injected into a mold. Fiber-direct compounding (FDC) has been a recognized alternative to molding pre-compounded long-glass-filled materials since at least 2012—one that can lead to better properties and cut costs. So why hasn’t it caught on?

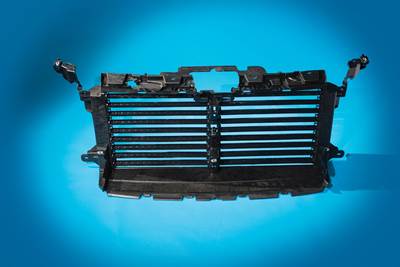

Well, to begin with, it’s not like a molder can just buy the necessary equipment and easily start competing for long-glass-fiber applications. The process is designed to make tough, technical parts—automotive is the primary target market—often as a replacement for metal, so these components need to be designed with the process in mind. This means key decisions need to be made in the design stage and must involve collaboration up and down the supply chain. Despite this challenge, there are commercial FDC applications in Europe, and several U.S. companies are looking seriously at the technology.

With the higher strength, the customer was able to design thinner wall sections, reducing total material use and cutting weight—a critical objective for auto makers.

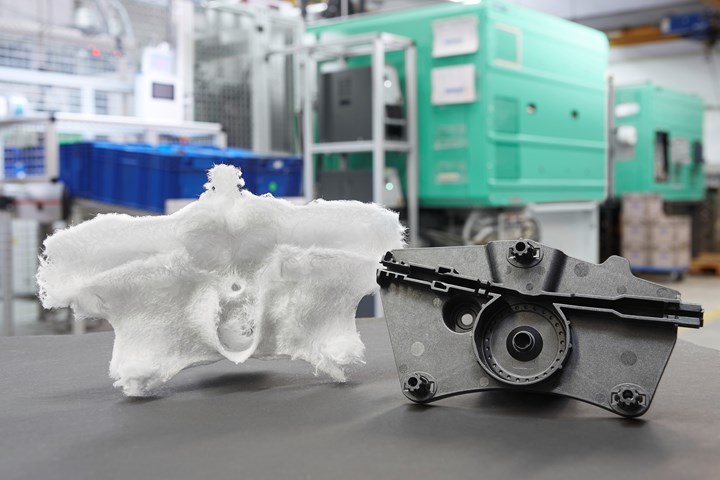

Consider deller plastics of Breckerfeld, Germany. This injection molder and moldmaker used FDC to make housings for a cable-drive unit used in automotive power windows (see photo below). Deller plastics had been using pre-compounded polypropylene (PP) with 30% glass but switched to Arburg’s FDC system in February 2018. It immediately reduced its material costs by almost 40%. Then, by feeding 11.2-mm glass to the process, deller was able to increase the length of the glass fibers in the molded part by about 50% compared with the compounded material. This precisely matched product strength and stability requirements. With the higher strength, the customer was able to design thinner wall sections, reducing total material use and cutting weight—a critical objective for automakers.

Nils Braselmann, along with his brother, Jann, and father, Uwe, runs the deller plastics family business, founded in 1959. Application of FDC helped keep the German company competitive in the global arena. “Following implementation of the FDC process, we were able to continue production in Germany, while remaining internationally competitive,” Braselman says. “We reduced our product and manufacturing costs to such an extent that we were able to offset our global logistics expenses.”

Deller plastics cable-drive housing component (top right) and the ashed part showing glass fibers.

How It Works

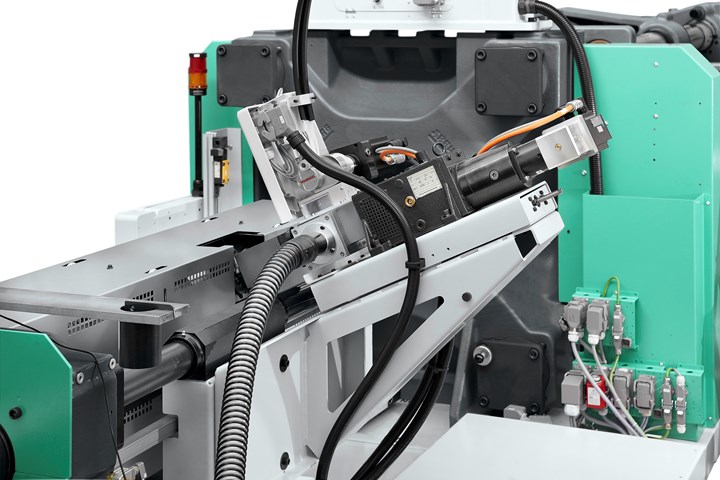

An FDC system involves an otherwise standard injection molding machine fitted with a modified barrel and a special two-stage screw, plus a servo-electric side feeder with integrated cutting device.

FDC side feeder with cutter mounted on a modified barrel.

In operation, continuous glass rovings are fed to the cutter, with the number of blades determining the length of the reinforcements. Fibers can be cut up to 50 mm long in theory, but 33.6 mm has been the maximum used so far. Cut fibers are fed through a port in the machine’s barrel, where they are incorporated into the melt. The first stage of the screw plasticates the resin while the second stage mixes in the glass and homogenizes the compound before injection.

Improved Mechanical Properties

The most important reason for using fiber-reinforced plastics is their greater mechanical load-bearing capacity, which is not temperature-dependent. Distortion, creep and energy absorption are similar to those of metals, however with the benefits of thermoplastics.

The part, the mold and the hot-runner system should all be designed with long fibers in mind.

The most significant factor in increasing strength and toughness is the length of glass fibers (Fig. 1). While almost any glass reinforcement will deliver an immediate increase in rigidity, a truly noticeable effect on strength and toughness is achieved only when fibers in the finished part reach and exceed a length of 1 mm.

In reality, it is extremely difficult to predict the length of fibers in the final part because the length will depend on several factors (Fig. 2). Material characteristics such as melt-flow rate and process parameters like screw speed and backpressure during plasticating are especially important, but so is injection speed. The hot-runner system also has a big influence on the fiber length. In fact, the part, mold and hot-runner system should all be designed with long fibers in mind. This means, for example, that large-diameter hot runners, smooth transitions and large gates are all very important. Depending on application requirements, each of these elements must be considered carefully.

In the end, the advantages of the side-feeding FDC approach are especially evident when examining the length of the fibers that can be incorporated in the final part. Figure 3 compares the final fiber length using FDC versus long-fiber granulate in a PP airbag housing. When a conventional pre-compounded long-fiber material is used, only about 30% of the fibers are longer than 2 mm. With FDC, feeding 16-mm fibers, the percentage of fibers that are at least 2-mm long increases to about 50%.

Clearly, when there is less damage to the fibers during melt preparation, the strength of the components increases significantly. Properties can be controlled in a more targeted way through custom adjustment of fiber length, fiber content and material combinations. For instance, if a glass loading of 23% meets performance requirements, then that exact loading can be achieved simply by adjusting the glass feeder settings. It is not necessary to buy custom compounded pellets or choose between standard 20% or 30% glass-filled materials.

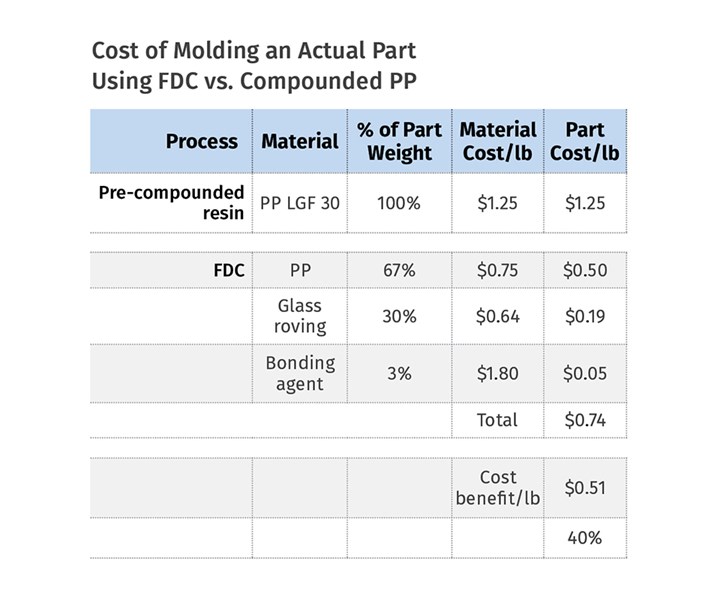

Lower Cost

As deller plastics discovered, FDC can dramatically reduce material costs in glass-filled parts. Neat polymer is considerably less costly than reinforced pre-compounded resin, and bulk glass roving is quite inexpensive too. Only a small amount of a bonding agent is needed to ensure the plastic adheres to the glass fibers. In some cases, a colorant can be added to the bonding agent, simplifying the feeding process. Of course, actual costs will depend on the region in which the purchases are made and the amount of material purchased, but the accompanying table compares the cost of molding an actual part using FDC versus compounded PP.

Lighter Weight

Another one of the first adopters of the FDC process was ROS GmbH of Coburg, Germany. In 2012, the company was also molding a cable-drive housing for Brose, a global automotive supplier (photo below). This component, however, was molded in glass-reinforced PBT, a relatively expensive material. “At that time,” recalls Steffen Tetzlaff, ROS’s managing director, “we were thinking about potential ways of lowering our manufacturing costs. Because we had already exploited most of the mold technology possibilities, we examined the material costs in greater detail and recognized that FDC would offer us significant benefits.”

ROS began evaluating the idea of replacing the PBT with PP and 30% glass fiber. The quality requirements were high. In addition to dimensional stability, strength was an especially important factor, requiring 50% of the glass fibers to be at least 1 mm long.

Brose cable-drive housing component (right) and the ashed part showing glass fibers.

The results speak for themselves. The cable-drive housings, which measure 7.87 × 3.9 in. and weigh 1¾ oz, were made of 30% glass-reinforced PP. They exhibit toughness, strength and rigidity comparable to the PBT version, but they are up to 30% lighter and can be produced with a shorter cycle time of just 33 sec. In recognition of this achievement, Brose awarded ROS for implementation of innovative ideas in 2017. ROS produces about 1.5 million fiber-reinforced parts each year on its FDC machine.

Hybrid Processing With FDC

Fiber direct compounding was developed for use on conventional injection machines. However, it can also be used in combination with thermoplastic composite sheet to achieve exceptional strength-to-weight ratios.

The ready-to-use composite part is produced in just 50 sec, while it takes several days to produce the same part in metal.

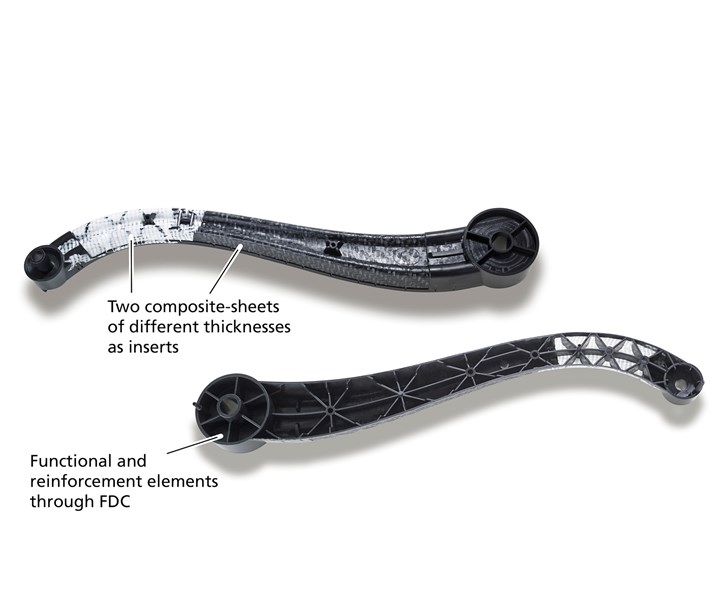

One such high-strength, lightweight composite application is an automobile brake pedal (photo below). In order to increase the strength and rigidity of the component, two thermoplastic composite sheet sections of different thicknesses are inserted into a single-cavity mold, where they are formed and overmolded using FDC to add reinforcing ribs and other functional details. The whole process is automated using a six-axis articulated-arm robot to insert the sheet and remove the finished part.

Automotive brake pedal, molded with FDC and thermoplastic composite inserts, saw failure threshold increase by 117% vs. FDC alone, while weight dropped to less than half that of metal.

The composite sheets raised the failure threshold when a load is applied by 117%, compared with FDC alone. A comparison with metal parts indicates a significant weight benefit too. The same part made from metal, weighs 533 g, while the composite pedal weighs only 202 g. The differences become even more pronounced in the production process. The tested, ready-to-use composite part is produced in just 50 sec, while it takes several days to produce the same part in metal.

Better physical properties, lower costs and the flexibility to tailor glass length and content to exactly match application requirements—these are just some of the reasons why fiber-direct compounding deserves a closer look.

ABOUT THE AUTHOR: Manuel Wöhrle, Arburg senior sales manager, Lightweight, has worked for Arburg in Germany since 2003. As part of the Turnkey department, he was initially responsible for designing and coordinating complex automation projects. Since 2015, he is the central point of contact for lightweight construction and is leads the sales team in that department. Contact: contact@arburg.com; arburg.com.

Related Content

In Sustainable Packaging, the Word is ‘Monomaterial’

In both flexible and rigid packaging, the trend is to replace multimaterial laminates, coextrusions and “composites” with single-material structures, usually based on PE or PP. Nonpackaging applications are following suit.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreRead Next

Long Fiber PP Compounds Drive Innovation in Automotive

Long fiber thermoplastic polypropylene ( LFT PP) is now widely used in automotive front-end carriers, instrument-panel carriers, door panels, consoles, pedals, under-body shields and more.

Read MoreInjection Molding Troubleshooter: Common Mistakes in Long-Fiber Molding

As the superior mechanical properties of long-fiber compounds attract growing popularity among OEM designers, an increasing number of injection molders are being introduced to these materials for the first time.

Read More