UC Berkeley Creates 3D-Printed Cap That Checks Food Safety

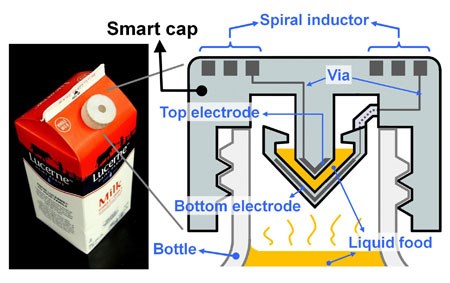

The proposed “smart cap” features 3D-printed plastic with embedded sensors to measure the freshness of liquid food.

The proposed “smart cap” features 3D-printed plastic with embedded sensors to measure the freshness of liquid food.

How many times have you thrown away a food item because the “sell by” date has passed? You're not alone. Those confusing labels oftentimes fail to tell us anything about the safety of food. Food waste isn’t some small problem either—the U.S. throws away about $165 billion worth of food each year. But new technology from UC Berkeley engineers may assist with this issue.

UC Berkeley engineers, in collaboration with Taiwan’s National Chiao Tung University, have been working on developing 3D printing technology that also includes include electrical components, such as resistors, inductors, capacitors and integrated wireless electrical sensing systems. Their latest innovation is to print a wireless “smart cap” for a milk carton that detects signs of spoilage using embedded sensors, according to a news report from the university.

“Our paper describes the first demonstration of 3D printing for working basic electrical components, as well as a working wireless sensor,” said senior author Liwei Lin, a professor of mechanical engineering and co-director of the Berkeley Sensor and Actuator Center. “One day, people may simply download 3D printing files from the Internet with customized shapes and colors and print out useful devices at home.”

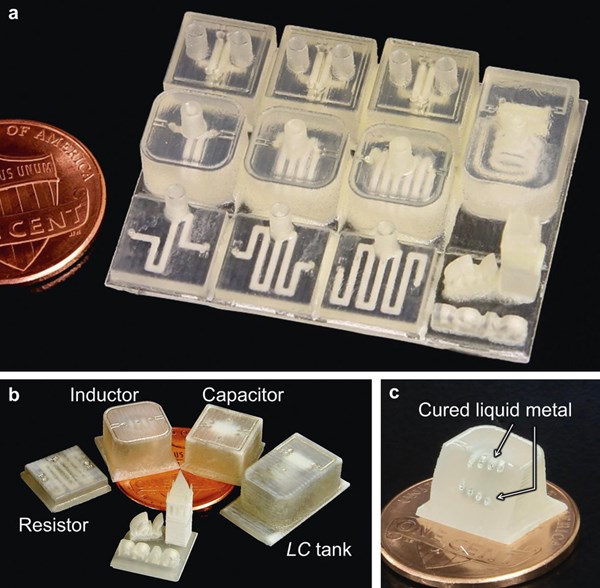

We know how much polymers are used for 3D printing, however, when it comes to conductors of electricity, the material can be a poor candidate. So the researchers produced a system that used both polymers and wax to still take advantage of 3D printing to produce an object. After the print was completed, the researchers removed the wax, leaving hollow tubes into which liquid metal – silver – was injection and cured. They produced various electronic components using this method.

The UC Berkeley engineers created a variety of 3D-printed electronic components including resistors, inductors and capacitors.

The researchers then integrated the electronic components into a plastic milk carton cap to monitor signs of spoilage. According to the university, the “smart cap” was fitted with a capacitor and an inductor to form a resonant circuit. A quick flip of the carton allowed a bit of milk to get trapped in the cap’s capacitor gap, and the entire carton was then left unopened at room temperature (about 71.6 degrees Fahrenheit) for 36 hours.

The circuit could detect the changes in electrical signals that accompany increased levels of bacteria. Those changes were detected wirelessly using the smart cap, which found that the peak vibration frequency of the room temperature milk dropped by 4.3% after 36 hours.

“This 3D-printing technology could eventually make electronic circuits cheap enough to be added to packaging to provide food safety alerts for consumers,” Lin said. “You could imagine a scenario where you can use your cellphone to check the freshness of food while it’s still on the store shelves.”

Lin said his lab is working on developing this technology for health applications.

The findings are published in a new open-access journal in the Nature Publishing Group called Microsystems & Nanoengineering.

Related Content

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreFreeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

Read MoreDuPont Buys Medical Product Manufacturer Spectrum Plastics

Purchase price of $1.75 billion for leading supplier of extruded, molded, and 3D printed medical components.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More