Freeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

New designs of medical device components demand a higher level of testing and scrutiny due to the critical nature of their uses and the potential consequences of failure. In health care settings, a malfunctioning device can have life-threatening implications. Rigorous testing is essential to de-risk new designs by ensuring that components function safely and effectively. For this testing to provide meaningful results, the parts need to be representative of production parts. Investment in a steel production tool can be a risky decision point for a product developer, putting leaders in the position of committing to a design that may later need to be changed based on verification and validation test results.

SPT Vilecon, a development and manufacturing services provider in the medical device and pharmaceutical industries, has implemented a prototyping process that de-risks and accelerates the development process by going directly to a representative, injection molded part. Without creating a steel tool. The process is Nexa3D’s freeform injection molding technology (FIM), which uses additive manufacturing to create single-use, dissolvable injection molds.

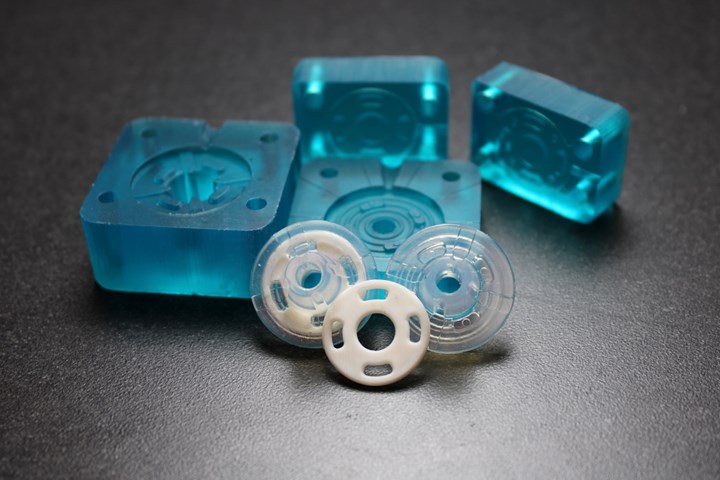

Printed molds along with molded medical device component prototypes. Photo Credit: Nexa3D

The flexibility, biocompatibility and stability of silicone make it an essential material for medical device components. However, these components can be challenging to prototype. Thermoset materials such as silicone cannot be melted and built up the way a thermoplastic material can be. There are ways of printing silicone parts, but the results are not as precise and not comparable to injection molded parts. Precision is especially important for medical device assemblies, such as those made by SPT Vilecon.

A Shortcut to Injection Molded Parts for Product Testing

The FIM process starts with a 3D printed mold, its design is the inverse of the desired part and printed from Nexa3D’s xMOLD resin. Once the mold has been printed and assembled, it is placed in a mold base in the injection molding machine. The mold base may be a simple metal plate or a more elaborate master unit die, depending on the application. Material is injected into the cavity to form the part, and the cavity and part are ejected from the mold base to cool. The tooling is compatible with standard injection molding machines, and no special modifications are required.

The mold and part are then placed in Nexa3D’s xWASH-FIM device. In the washing chamber, the resin is dissolved in solvent, leaving the finished part behind. Besides getting to an injection molded part more quickly, the process also removes some geometric constraints on molding that can require additional tooling in other situations. Unlike a traditional mold, a dissolvable mold does not have to release the part after injection.

“xMOLD is unique in enabling us to manage complex part features with ease, as we can simply dissolve the mold elements that will normally require high-cost steel mold elements like sliders or collapsible cores,“ says Lasse Staal, director of freeform injection molding at Nexa3D.

According to Staal, the same characteristics that make FIM a good solution for medical device development also make it a good choice for other highly regulated industries, such as aerospace and automotive.

“Because errors discovered after we have sourced our metal tooling are expensive and time-consuming to fix, freeform injection molding allows us to replace the binary ‘invest-before-you-can-test’ paradigm of metal tooling with a gradual migration from prototyping that promotes a much higher decision quality, along with lower costs, shorter lead times — and happier development teams,” Staal says.

According to SPT Vilecon CEO Bjarne Andersen, FIM saves customers both time and money. By getting testing done faster and on prototypes made with the right materials, Vilecon can get a design to a “fast fail” or to market sooner — whichever the case may be — thus shortening the time before a product starts generating revenue.

Related Content

PHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreExtrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreMasterbatch Creates Cavities, Helping Film Processors Boost Sustainability, Recyclability

Additive technology creates air pockets in film during orientation, cutting down on the amount of resin needed while boosting opacity, mechanical properties and recyclability.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More