Masterbatch Creates Cavities, Helping Film Processors Boost Sustainability, Recyclability

Additive technology creates air pockets in film during orientation, cutting down on the amount of resin needed while boosting opacity, mechanical properties and recyclability.

New additive technology promises to enable film processors to utilize less plastic and boost recyclability by creating nanoscale air pockets or cavities in the film while it is being stretched via either machine or biaxial orientation equipment. Orientation of the film is critical because the additives are designed to separate from the polymer during stretching to create these material-saving pockets. Between cavitation and orientation, processors utilizing this technology can expect to cut their resin usage by up to one-third.

So says VOID Technologies, the developer of the additive VO+, which is available as a pellet masterbatch. The technology was originated by Kimberly-Clark as part of a research initiative to promote more sustainable polymer applications. In 2015, VOID was launched as an independent company with the purpose of expanding the technology from lab-scale concept into a commercial product. Today, it has a 25,000-square-foot R&D lab and manufacturing facility in Neenah, Wisconsin, equipped with lab- and commercial-scale twin-screw co-rotating compounding extruders for R&D and production, and a pilot-sized blown film line with machine direction orientation (MDO) for R&D and trial work. VOID also has commercial teams in Canada and Europe.

“Kimberly-Clark developed the technology, and I had a good relationship with them as we had previously worked together on other projects,” says James Gibson, VOID’s co-founder and CEO, who led the spinout from K-C. “They thought it was really exciting and innovative technology, but also felt it was more relevant to markets outside of their core focus.”

This led to what Gibson describes as a “two-year incubation project where we took the value proposition of putting cavitation into polymers and figuring out whether anyone in the world cares about it.” The “overwhelming feedback” Gibson received from visiting companies throughout the flexible packaging supply chain was that lightweighting polymers without sacrificing mechanical properties was extremely appealing. Gibson says, “I had to figure out very quickly what section of the very large plastics industry we were going to focus on and, after a couple of twists and turns, we decided to heavily focus on opaque films, primarily polyethylene.”

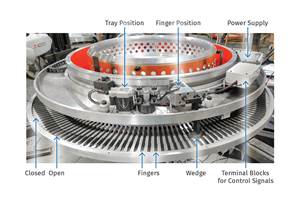

VOID’s plant in Wisconsin houses twin-screw compounding extruders for R&D and production runs. Source: VOID Technologies

Gibson notes that, over the last few years, more and more film processors are adding orientation equipment to their production lines to develop recycle-ready PE packaging applications. He elaborates, “We’re seeing a big adoption of MDO technology in the film market. Some film processors are on their third, fourth lines already, and with more on order.”

The technology is covered by roughly 35 patent families with more than 300 territory patents. Gibson divulged that its proprietary masterbatch formula “relies on multiple polymers with different types of chemistry” to create the cavities, which he explains result in density reductions. What’s more, the voids in the polymer diffract light, which he says creates high levels of opacity without need for TiO2.

“What’s unique about the masterbatch is that different parts of the formulation can be tuned to achieve different attributes,” Gibson adds. So you can tailor for more density reduction or more opacity driven, and that’s why we think polymeric cavitation is really special.” The masterbatch is available in pellet form. The masterbatch is typically dosed at about 10% of the overall formulation, Gibson says, adding, “you end up with only about 6% of non-PE additive in the final film structure, and that’s super important for recyclability.”

“We’re seeing a big adoption of MDO technology in the film market. Some film processors are on their third, fourth lines already, and with more on order.”

Trial Runs

VOID has conducted several commercial-scale R&D trials using VO+ technology in Germany at the global headquarters of both Windmoeller & Hoelscher and Hosokawa Alpine. Utilizing blown film lines equipped with inline MDO, the trial focused on a variety of PE film structures for applications such as all-PE laminates (sealant films and mid-ply), wicketed bags and flow wrappers, Gibson explains. The properties of these voided films varied depending on the PE used and the specific production conditions, such as extrusion and MDO stretch ratio/temperature.

In Wisconsin, VOID also houses pilot-sized blown film and orientation equipment to trial formulations.

Says Gibson, “For example, we’ve run several trials on W&H and Alpine equipment to produce films for applications such as midwebs, sealant films and wicketed bags. These applications are typically based on LLDPE/m-LLDPE-rich film structures. During these trials, we have produced 25-90 µm voided films with low density (0.80-0.85g/cm3) and opacity without TiO2 (50-70% depending on film gauge). These films have also been able to achieve excellent Dart Drop performance (for example, >1000g in a 50µm film), which can enable customers to downgauge and save even more material.

“We’ve also run trials to produce film structures for flow wrappers for confectionery packaging. This application requires relatively high stiffness and high opacity in a thin film, so we used HDPE resins (for stiffness) and a small amount of TiO2 to boost opacity. In these trials, we’ve been able to produce 30-40 µm films with densities between 0.83 and 0.90g/cm3 and opacity as high as 70%.

“Importantly for this application, it’s not possible in films thinner than 35 µm to achieve the high opacity requirements with just TiO2 without increasing density above limits for recyclability set by the Association of Plastics Recyclers/How2Recycle (0.996g/cm³) and RecyClass (0.970g/cm³). Gibson notes that at thickness levels below 35 µm, film processors that need a high level of opacity in their structure traditionally add relatively high levels of TiO2. This results in film density reaching the levels of 0.97-1.00 grams/c3. Such films, he says, are deemed to not be recyclable by APR or RecyClass in a sink float separation system. “Processors want high-opacity thin films, but they can't do it with TiO2 alone because it's heavy.”

Figure 1 – VOID explains that PE film cavitation created by its proprietary masterbatch during orientation results in low density and high opacity, with the internal structure scattering light instead of pigments.

In cast film, Gibson notes that, as with blown film, its additive technology requires a postextrusion orientation step to generate cavitation. He notes, “Initial pilot-scale tests in cast biax PE film have shown very positive results, and we plan to conduct larger scale tests in 2025. We have also achieved very encouraging results from pilot-scale tests using a different VO+ masterbatch in polyester films (cast film with transverse direction stretch) for applications such as labels.” While VOID has conducted trials with inline orientation, Gibson notes that the additive technology can also be used by film processors that run their stretching equipment offline.

Figure 2 – VOID says its VO+ patented additive creates nanoscale air pockets that create high-performance films with a reduced environmental footprint.

Commercial Launch

In addition to VOID’s R&D trials on Alpine and W&H lines, Gibson notes its customers are also doing an extensive amount of converting trial work, including end-to-end supply chain trials, to develop new MDO-voided films and packaging applications. In fact, earlier this year Charter Next Generation (CNG) expanded its GreenArrow line of sustainable films with a new line of cavitated recycle-ready PE films for flow wrap and confectionery applications. Using VOID’s patented VO+ masterbatch on an MDO-equipped blown film line, CNG produced high-performing PE film structures that are opaque yet compatible with existing PE recycling streams.

Adoption of MDO PE film is a rapidly growing industry trend as it enables recyclable, high-performing flexible packaging. By using VO+ Masterbatch, CNG can now produce thin-gauge voided MDO PE films that offer a combination of low density and high opacity not achievable with mineral additives such as TiO2 pigments or CaCO3 cavitation agents. This innovation creates a unique PE-based, recycle-ready alternative to conventional polypropylene-based substrates that often require biaxial orientation.

“CNG continues to raise the bar and reinvent packaging with a sustainability-first mindset. Using VOID’s patented VO+ technology enables us to achieve the high opacity, ease of processing and recycle-ready performance we are targeting for these films. This in turn allows our customers to reduce their use of virgin materials and process their packaging in existing polyethylene film recycling streams,” says Brent Greiner, CNG’s vice president of technology.

Building on initial launches, over the next months Gibson says VOID and customers both in North America and elsewhere in the world are expected to conclude more than 30 industrial-scale production trials utilizing the VO+ technology.

Related Content

Purpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

Read MoreNew Blown-Film Cooling Technologies Set to Debut at NPE2024

Cooling specialist Addex to roll out new auto-profiling air ring for rotating dies, and new single-plenum air ring.

Read MoreFor Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More