Windmoeller & Hoelscher Corp.

23 New England Way

Lincoln, RI 02865 US

800-854-8702 | 401-333-2770

info@whcorp.com

whcorp.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Windmoeller & Hoelscher Corp. Supplies the Following Products

- Bag-making Machinery

- Coextrusion Dies, Feedblocks

- Extrusion Dies

- Film Take-off Systems

- Flexographic, Rotogravure Equipment

- Single-screw Extruders

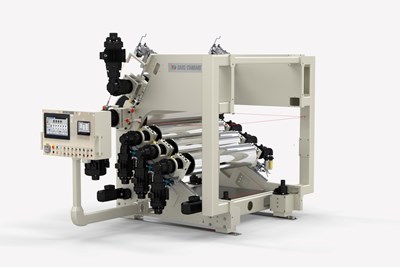

- Web Winders, Unwinds, Rewinds

Editorial, News, and Products

-

Leading Cast Film Processor Adding Blown Film Capacity

Malpack adds two multilayer blown film lines for agricultural, stretch hood and shrink films.

-

Masterbatch Creates Cavities, Helping Film Processors Boost Sustainability, Recyclability

Additive technology creates air pockets in film during orientation, cutting down on the amount of resin needed while boosting opacity, mechanical properties and recyclability.

-

W&H Expanding Office, Warehouse in Rhode Island

Expansion said to strengthen support and foster further growth in North America, says builder of film extrusion and converting equipment.

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

Filtration System Helps Film Processor Manage Recycled Material Mandates

Global film processor RKW teams with Nordson to enable it to process blown film with high recycled content.

-

W&H Names VPs for Sales, Service

Fairbarn to lead sales efforts; Utovac service.

-

Windmoeller & Hoelscher Adds Regional Sales Manager

Film extrusion and printing machine builder adds Ken Register to sales roster.

-

More Automation Comes to Blown Film Processing

New system for cuts in half the time to move from one product format to another.

-

Green’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

-

Pregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

-

W&H Adds Kasie Fairbarn as Product Sales Manager

Fairbarn joins blown film machine builder with experience from both processor and brand owner sides.

-

Productivity & Profitability ‘Turbo' Charged At Young, Growing Film Processor

Polymer Film & Bag adds extrusion capacity and new technology to make its two-year-old processing business more efficient.

-

Pregis to Invest $32 Million at Michigan Blown Film Site

Processor responding to increased demand for high-quality films.

-

James Feeney, First President of W&H Corp., Dies

Long-time leader of W&H’s U.S. operations was 85.

-

Steinbeck Named CEO of W&H

Succeeds long-time CEO Jürgen Vutz, who will join the company’s Supervisory Board beginning the new year.

-

Film Processor Boosts Line Performance with Air-Ring Retrofit

Air-ring upgrade results in output gains up to 23% for leading film processor in Indonesia. Gauge uniformity also improved.

-

‘Game Changing’ Flat Die Lives Up to Its Billing

Revolutionary ‘touchless’ die and control system for cast film and coating/laminating offer speed, efficiency and operational efficiencies to processors that were previously ‘unheard of.’

-

W&H: Virtual Expo a Success

More than 2000 visitors from 120 countries tuned in for live flexographic and gravure press demonstrations, technical sessions and virtual meetings.

-

Film Extrusion: Towers of Power & Sustainability

At K 2019, developments in blown film highlighted recyclable film structures for new applications and technology aimed at making product changes more efficient.

-

Packaging Converter Launches Film-Extrusion Business

Polymer Film & Bag Inc. will start with three-layer capacity of more than 20 million lb/yr, with additional expansion plans already firmed up.

-

Polykar Adds Third W&H Multi-Layer Line

New Optimex adds seven million lb of capacity.

-

W&H Names Paepenmüller as CTO

Assumes responsibility for machine builder’s three business units: extrusion, printing and converting.

-

Sigma Plastics Continues Equipment Investment Spree

Film processor closed deals on 13 new lines during NPE2018. Adds four more from W&H, Reifenhauser.

-

Accredo’s Credo: Designed for Sustainability, Built for Success

In fewer than 10 years, Accredo Packaging has developed innovative packaging solutions—including the first-ever all-PE barrier standup pouch—while maintaining its commitment to being ‘green.’

-

News Highlights from NPE2018

Developments in Industry 4.0, multi-layer preform molding, automation, LSR processing, and PP were among the major newsbreakers at May’s show. And one film processor finalized purchases of 13 new lines.

-

Windmoeller & Hoelscher and Keep Blackstone Valley Beautiful Team up For Litter Clean-up Day

In under two hours, the group of 10 collected more than 20 bags of garbage, including cans, bottles and wrappers.

-

NPE2018 New Technology Focus: Film & Extrusion Coating

Check out what’s new in blown and cast film and extrusion coating at the big plastics industry trade show.

-

Not Running, But Still Pushing Technology Envelope in Film Extrusion

W&H sees options in retrofitting game-changing quick-switch technology.

-

Extrusion/Compounding at NPE2018: More…More…More!

More speed, flexibility and robustness. Across a gamut of extrusion applications, machine builders are introducing new machinery, components, and systems to dramatically raise the bar on productivity.

-

Savvy Vietnamese Firm Launches All-PE Laminated Pouches

Thanh Phu’s ‘Veloflex’ converting technology results in packaging with optics similar to conventional laminated structures but is readily recyclable.

-

K 2016 Extrusion: Speed, Versatility Rule the Day at K

Shorter product runs mean frequent product changeovers for processors, and suppliers responded to these trends across all extrusion technologies.

-

Michael Andrews Joins W&H

Will head up processing technology and application development.

-

New Film Resins’ Performance Demonstrated by Several Equipment Makers at K 2016

Take a look at a video discussion between ExxonMobil Chemical and W&H on processing the new Exceed XP resins.

-

Next Generation Films Plans Big Expansion

Ohio processor to spend $75 million on new facility, equipment.

-

K 2016 Preview: Extrusion and Compounding

Regardless of what you might be extruding, the themes of speed and flexibility will loom large in extrusion at the giant show.

-

Film Processor Pregis Invests $17 million in Expansion

Firm announces name change to Pregis Films in light of 2015 acquisition

-

On-Site: The Buck Stops Here

Fully integrated manufacturing and an unwavering commitment to quality has helped position NELMAR as the ‘gold standard’ in tamper-evident security bags.

-

What You Need to Know to Make World-Class Stretch Film

Advances in materials, feedblock/die technologies, and winding can help processors develop more sophisticated cast-stretch products.

-

EXTRUSION AND COMPOUNDING NPE: Flexibility, Speed and Quality

Extrusion processors need more—of everything—to compete. And suppliers responded in force in Orlando.

-

EXTRUSION AND COMPOUNDING AT NPE: The Word Is ‘More’

As in speed, power, quality, flexibility, layers, and efficiency. Those are the trends across all extrusion processes.

-

Giving employees the time, resources to “go back to school”

Consistent production is the number one priority at any plastics processing plant, but how much do most companies do to train technicians before they hand over the keys to hugely expensive (and complicated) machines that are at the heart of production?

-

Things Are Adding Up Nicely For Charter NEX Films

Since Charter Films merged with NEX Performance Films about 18 months ago, the combined operation has melded the best capabilities of each company into a single business churning out a wide scope of blown films.

-

Back to Its Roots in Film Extrusion

After drydocking its film extrusion business in '99, converter goes back to its roots with upstart sister company.

-

Lots of Expansion Brewing In Film Extrusion

Firms adds more capacity to produce higher-tech films.

-

From Printer to High-End Extruder: Colormasters Sets Sights on Collation Film

When long-established printing and converting company Colormasters was putting together a strategic plan for growth, it added blown film processing to the mix.

-

Exxon to Film Processors: Go With Five Layers

For a company that did not exhibit at K 2013, ExxonMobil Chemical certainly was busy at October’s Dusseldorf trade show. Material from the Houston-based resin giant was running on a handful of film lines producing everything from five-layer collation-shrink blown film to five-layer hygiene film, three-layer lamination film, and 33-layer nano-cast stretch film.

-

Extrusion/Compounding at K 2013: Having It All

Extrusion processors no longer need to chose among speed, quality, and flexibility, based on exhibits at K 2013.

-

Headlines from the K 2013 Show

Here’s just a taste of the innovations on display, a selection of the top headlines not covered in our September show preview.

-

Blown Film Line Combines Style, Substance

WEB EXCLUSIVE: Three years in the making, unique Varex II blown-film line from W&H that debuted at K 2013 features clean, sleek look and offers upgrades in throughput and control as well.

-

K 2013 Preview: Extrusion, Compounding, Recycling

Across all extrusion technologies, expect to see new standards in speed, quality, flexibility, and efficiency in both energy and material usage.

-

Packaging Powerhouse Does It All

Materials formulation, cast and blown film extrusion, sheet extrusion, printing, and laminating come under one roof at this processor.

-

ISO Poly Avoids Economic Woes With High-Value Films

Positioning itself on the high end of the blown-film market helped insulate this blown film processor from the recent economic downturn.

-

First U.S. Optimex Line Lets Film Processor Return to Its Roots

'Time was right' for firm to venture back into blown film.

-

Better, Not Bigger, Is How Copol Wins In CPP Film

Small player in a large market speaks in a loud voice.

-

On Site: Where Art, Science, And Customer Focus Meet

Business strategy at Danafilms involves a mix of art and science in blending resins, designing layer structures, and operating flexibility for both short and long runs.

-

EXTRUSION & COMPOUNDING: Five-Layer Film Structures Set to Supplant Three Layers?

In blown film, equipment and material suppliers have come together to push five-layer technology into non-barrier applications previously held by three-layer films.

-

First Microlayered Commodity Films

Advanced microlayer feedblock technology, used for over a decade to put dozens or hundreds of alternating layers into specialty films, has passed a new milestone.

-

K 2007 Extrusion: Extrusion Outputs Go Through the Roof

Dramatic production demonstrations of cast and blown film set throughput records on the show floor in Dusseldorf.

-

What's New at the Show in EXTRUSION

It’s all about higher speeds and higher outputs at this year’s “K” show in Germany.

-

NPE 2006 News Wrap-Up: Extrusion

NPE 2006 presented a bevy of features to make film, sheet, pipe, and profile extrusion more efficient.

-

Nine-Layer Blown Film: Why It's a Challenge, What It Takes to Succeed

Eight years after nine-layer blown films were first introduced, only a handful of processors have mastered the challenges of making them. Machine suppliers are now setting up lab lines that could make entry easier.

-

Capacitance Thickness Gauges: New Designs Break Old Barriers

Economical, non-nuclear capacitance gauges are opening new markets in blown film—primarily in barrier films, where they previously suffered serious shortcomings. New gauge designs, and new ways of mounting them, make capacitance technology much more flexible.

-

K 2004 Extrusion: Outputs Rise, Downstream Units Gain Flexibility

The show was packed with new equipment for pipe and profile, including extruders redesigned for higher outputs and/or lower cost, plus new ways to adjust die and calibrator diameters or switch dies and calibrators more quickly.

-

K 2004 News Preview: Extrusion

At K 2004, at least a half-dozen European machine builders will show new direct-drive extruders running gearless—or nearly gearless—drives with substantially higher rpm and output rates than conventional extruders of the same size.

-

Automatic Gauge Control: Comparing the Options

Until recently, blown-film processors looking for auto-gauge control had a choice of one segmented-die system, one IBC-based system, and several segmented air rings. Now there are at least nine auto-dies, including two for high-stalk bubbles, and lots of air-ring variations. All claim to improve gauge uniformity, but there are differences.

-

Winders: They're Pushing New Limits In Speed and Tension Control

New-generation winders for blown and cast film are winding bigger, better rolls at higher speeds and lower tension. They've gotten so fast that cast film lines can now realize their full productive potential.

-

A Show Full of Surprises For Every Application

It doesn’t matter whether you extrude blown or cast film, sheet, pipe, profiles, or foam—the K 2001 show held something exciting and unexpected that will open your eyes to new possibilities.

-

Extrusion (K 2001 Preview)

Probably the most intriguing news in extrusion at K 2001 will be a novel way to extrude clear film that differs from standard blown and cast methods.