Extrusion (K 2001 Preview)

Probably the most intriguing news in extrusion at K 2001 will be a novel way to extrude clear film that differs from standard blown and cast methods.

Probably the most intriguing news in extrusion at K 2001 will be a novel way to extrude clear film that differs from standard blown and cast methods. This process, which has seen several variations since it was first tried by Union Carbide in the 1950s, drops a sheet or “curtain” of melt from a flat die, cooling it initially just with air and then by lightly “kissing” it between polished metal belts or a belt and a cooling roll. This method is said to impart very low stress and high gloss and clarity. And unlike the other methods, this “third way” polishes both sides of the film. During the K’98 show, Reifenhauser demonstrated such a process in its plant in Troisdorf, Germany.

This year’s K show will see the launch of a curtaining process from SML Maschinengesellschaft in Lenzing, Austria (U.S. office in Chicago). Called SML Sleeve-Touch, it will be demonstrated live via video of a commercial-scale line running at SML’s plant. SML will fly customers to Austria during the show to see the process.

SML licenses Sleeve-Touch technology from Chiba Machine Industry Corp. in Chiba, Japan. Chiba is one of four Japanese companies that have sold 15-20 commercial installations of belt-polishing processes in Japan and Europe. These are used to make high-clarity PP film for blister packs, reclosable yogurt lids, stationery folders, and cosmetics packaging. (For details on a curtaining process for license from Rohm and Haas Co. in Philadelphia)

Up to now, all these belt-polishing processes have been limited by low line speeds. SML reportedly has made major improvements in cooling to raise productivity. SML’s Sleeve-Touch line makes 70-in.-wide PP film at up to 200 ft/min. It has high gloss, low haze, no die lines, low orientation, low stress, and high optical clarity, SML says. Thickness range is 0.75 to 5 mils.

Sleeve-Touch film comes out of a vertical die and is cooled at very low pressure between one chill roll and a continuous metal belt or sleeve. The roll and belt can impart glossy or matte surfaces. SML’s first production line was built earlier this year. It is unusually flexible in that it can be adapted to make conventional cast or calendered film.

Seide Engineering in Buchholz, Germany, has also developed a new belt-polishing unit that works with the adjustable roll stack that Seide introduced at K’98. Though it won’t appear in Dusseldorf, the new polishing unit will be demonstrated making thin PP film at Seide’s lab during the show.

Blown film news

Show entries in blown film focus on higher productivity and better gauge control. Gauge control is typically a bigger issue in Europe, where film is sold by the meter, than in the U.S., where it’s sold by the pound. But U.S. interest is growing, since better film quality means flatter rolls and higher productivity for downstream converters.

The expiration last February of Windmoeller & Hoelscher’s patent has opened the door for additional automatic dies that use selective heating of sections of the die lips to control film gauge. Three firms taking advantage of this opportunity are Hosokawa Alpine AG (with U.S. office in Natick, Mass.), Reifenhauser GmbH (U.S. office in Ipswich, Mass.), and Kiefel Extrusion GmbH (Wrentham, Mass.).

Alpine’s new gauging system will be demonstrated on a three-layer line with a 20-in. die. The die combines melt distribution similar to that of a plate die with conventional spirals. It was shown previously in a monolayer version at NPE 2000 in Chicago. Now it’s available for up to seven layers and up to 27 in. diam. It reduces overall die height from 5 ft to about 3 ft, which shortens residence time and reduces pressure drops. Alpine will also introduce new ExVis software to monitor the extrusion process and store product recipes and data.

Reifenhauser will also show a three-layer blown-film line at the show capable of 880 lb/hr. It uses the company’s latest thermally based automatic die-control system, called REIcotherm.

Other news from Reifenhauser includes a small direct-drive coextruder for blown or cast film and a screw design that can run LLDPE, LDPE, HDPE, and metallocene resins. Reifenhauser now offers not just complete systems but stand-alone components like extruders, dies, gauge-control systems and winders.

Kiefel will run its new Kirion fully automated three-layer line at the show with a new automatic die using heated die segments. It will run a low-stalk bubble.

Meanwhile, W&H (U.S. offices in Lincoln, R.I.) will run its Optifil automatic die on a Varex three-layer line that is capable of 80% higher throughputs than ever before. The line has an 11-in. die designed for lower residence time. The system also uses a low-temperature screw.

New gauge-control systems utilizing an automatic air ring instead of the die will be shown for the first time by Addex Inc. of Boston. Its EGC (external gauge control) system was introduced this spring. A manually adjusted version, called MGC, will also be shown for the first time.

Addex will also display its first multi-layer REDI die with three layers. The three-layer prototype was built in August and has run customer trials. Addex has already designed five-, seven, and nine-layer REDI dies as well, but won’t build them until the three-layer die is fully proven out.

Kuhne GmbH (U.S. offices at American Kuhne in Norwich, Conn.) will show for the first time a new dual-lip version of its Tornado air ring that adds automatic gauge control and 50% higher cooling capacity. Kuhne will also demonstrate at its German plant the company’s first double-bubble film line with five or more layers.

Lots of new winders

Among new blown-film winders and other downstream introductions at K, Alpine will present a new machine-direction orientation (MDO) unit that can run in-line or off-line.

Davis-Standard Corp.’s blown-film div. in Somerville, N.J., is bringing a new center winder, model TEC-2, which winds at 300 ft/min and makes 44- to 84-in.-wide rolls of up to 30-in. diam. It also has a new lay-on roll to wind and transfer webs between stationary spindles, plus a swing-out hoist to support the roll while the shaft is being removed.

Kiefel’s new subsidiary, Wintech Winding Technology in Switzerland, will show a winder with patented CLP2 (constant lay-on pressure) system, which is said to guarantee minimum pressure and web tension for delicate films. The winder’s controls are newly integrated with the line controls, facilitating faster product changeovers and reduced scrap.

Kuhne will wind film at the show on a new Centroflex 520 winder, which combines center, surface, and gap winding and has a patented cutter built into the contact roll. The cutter extends pneumatically to cut film at a 90° angle. A patented vacuum roll handles very thin film.

Reifenhauser will also show its UFA III gap and contact winder, whose controls are newly integrated into the line controls. It can wind rolls up to 46-in. diam.

Addex will bring the prototype of a new winder for larger rolls. No details were available.

For cast film & sheet

Several equipment makers are bringing innovative feedblocks capable of quick changes of layers in coex webs. Black Clawson Converting Machinery Corp. in Fulton, N.Y., will show a feedblock for packaging and agricultural films. Unveiled as a prototype at NPE 2000, it’s now in commercial use making 14-layer agricultural film in the U.S. Processors can double the number of layers by stacking feed blocks.

Cloeren Inc., Orange, Texas, will show its new Rotatable Tuning Feedblock for the first time. Rotatable Tuning Pins alter layer structures by rotating a different face of a pin into the exit channel. This varies the geometry of the flowing material on the fly. The RT Feedblock can be configured for two to seven layers and used with a Cloeren selector-plug cartridge or “TopHat” device to change layer sequence.

Extrusion Dies Inc. (EDI), Chippewa Falls, Wis., is working on an altogether new die concept, which it says will be easier and faster to clean than conventional dies. Meantime, EDI plans to show a schematic of the first five-layer version of its patent-pending Accuflow feedblock, which allows layer thickness to be adjusted on the fly. The five-layer block was recently shipped to a customer. A three-layer version was shown at NPE 2000.

Kuhne will bring to the show a seven-layer, four-extruder cast-film line that will show off a new feedblock for thermoformable barrier film. The feedblock has a patented melt-bolt adapter that can rearrange the layers—for example, converting the unit to produce just three layers with a thick core and thin surface layers. The block can also encapsulate film edges with a monolayer strip so that expensive barrier resin isn’t wasted in the edge trim.

Battenfeld Gloucester Engineering and Battenfeld Extrusionstechnik in Germany cooperatively developed a new “global” thermoforming sheet line (TSL) for thin-gauge sheet with up to seven layers. The TSL line offers standardized components and global service but can still be customized for niche markets. It comes in four sizes for 850 to 1000 lb/hr of PP, PS, or PET.

Welex Inc. in Blue Bell, Pa., will show the 5-in., 30:1, single-vented World Standard sheet line for PET. This is a new size for Welex, which previously offered 4.5- and 6-in. extruders. It can run 2500 lb/hr of PET or HIPS. High-vacuum venting reportedly allows it to process PET with about a quarter of the usual drying time. It can make 40-in.-wide sheet 0.008 to 0.060 in. thick.

W&H will show a cast-film line with a new chill roll design.

And Battenfeld Gloucester will show a new cast-film winder for the first time. No details were available on either product.

For making multi-wall sheet, Breyer GmbH Maschinenfabrik in Singen, Germany, says it has developed a more effective vacuum vent that allows PC to be processed without predrying. Breyer, which has no U.S. representative, will also show a vacuum calibrator for multi-wall sheet that reportedly raises throughput to 1500 lb/hr.

News in pipe & profiles

Davis-Standard, in cooperation with a+g Extrusion Technology GmbH in Austria, a maker of downstream cooling and calibrating equipment, has developed a new high-output window-profile line, which will run at Davis-Standard’s plant in Erkrath, Germany, during the show. It has a GP 94 parallel twin-screw extruder with 28:1 L/D and will extrude dual profiles, one U.S. style and the other a heavier European style, at 1000 lb/hr.

Battenfeld Extrusionstechnik will also show downstream innovations for PVC window profiles, including a dry calibrator with a central vacuum pump and a new built-in haul-off that reportedly won’t dent profile surfaces. The firm will also display a high-output PVC window-profile line with four dry calibrators and three vacuum pumps, all connected to a common manifold to save energy, but still individually adjustable to different vacuum levels.

For pipe, Davis-Standard has new upgrades for its high-output grooved-feed system, which will be shown on a 3-in., 34:1 Thermatic extruder with a brand-new dual-barrier DSB-VI screw. The extruder was lengthened from 30:1 to 34:1 to increase residence time and handle higher volumes of melt. The screw has new feed-section geometry and a replaceable grooved feed bushing in the throat. The interchangeable grooved bushing allows processors to change from aggressive square grooves for stiff polyolefins like LLDPE or HDPE, to less aggressive semicircular or ratcheted grooves for LDPE, MDPE, or flexible PVC.

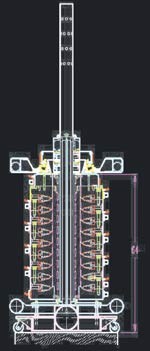

Krauss-Maffei GmbH in Munich (U.S. offices in Florence, Ky.) will show its latest twin-screw pipe line with up to 17% higher output than before. The extruder has 36:1 L/D and two vent zones. The first passive vent zone lets air escape while the powder is being compacted. The second zone has vacuum venting to pull volatiles from the melt.

Macro Engineering & Technology Inc., Mississauga, Ont., will demonstrate a new mixing section for a barrier screw.

Related Content

New Rotary Die and Cam Lock Design for Tubing

NPE2024: New design enables quick and easy assembly and disassembly of the crosshead, and eliminates the socket head cap screws.

Read MoreMaking Gains in the Drain Game

AWD blends extrusion and thermoforming technologies with plenty of home-brewed equipment and processes to keep water away from where it isn’t supposed to be.

Read MoreHigh-Output Extruder Series Now Comes in Smaller Size

Series offers higher output, lower melt temperatures and energy savings.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More