Unique Class of Polymers Behave Like Crosslinked Thermosets and Process Like Thermoplastics

ATSP Innovations’ Nowe polymer is designed for applications where PEEK, PES, PEI and phenolics and cannot deliver.

A new, unique class of polymers that behave as crosslinked-like thermosets but process like thermoplastics has been under development at ATSP Innovations, Champaign, Ill. The company is now actively seeking partners, collaborators and customers to bring these unique “next-generation wear solutions” technology to the industrial markets.

Founded in 2010, ATSP has laboratory and offices located in the University of Illinois at Urbana-Champaign (UIUC) Research Park. Its main goal has been the development, production and commercialization of a new family of resins that heralds a major advance for the field of polymers. Namely, combining the advantages of a high-temperature thermoset with the processing of a thermoplastic. ATSP’s polymers reportedly offer high thermal stability, wear resistance, and solid-state state bonding.

The ATSP polymers are targeted to applications where conventional polymeric solutions like PEEK, PES, phenolics, and polyimides (PEI) cannot deliver. The company has been developing unique polymer concepts with impact from structural composites ranging from launch vehicles to commercial automobiles, as well as low dielectric constant circuit boards for microelectronics, rigid structural foams, ablative material for reentry vehicles, and fast-bonding high-temperature adhesives.

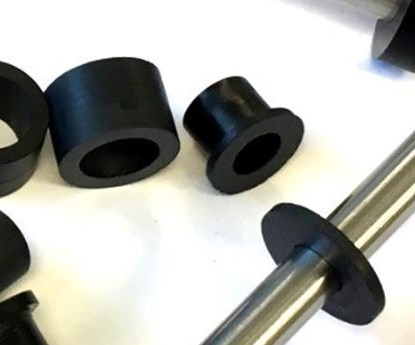

The new Nowe polymer uses a proprietary blend of ATSP polymer with reinforcements and solid lubricants. ATSP (aromatic thermosetting copolyester) is a new class of high-performance polymer that reportedly offers high dimensional stability and performance like thermosets while being recyclable like thermoplastics.

According to the ATSP team, Nowe can prove to be the perfect fit whether your application needs tight tolerances over the working life of the polymer; high durability; or low coefficient of friction while working at high temperatures. Like other polymeric bearings, Nowe also provides a light-weight corrosion and chemical resistant bearing.

One of the unique capabilities of all ATSP resins is a self-bond feature made possible due to interchain transesterification reactions. This technology reportedly leads to “zero-wear” as the wear debris can get reincorporated into the bulk.

Overall key characteristics include:

- Outstanding wear properties

- Low coefficient of friction

- High working temperature

- Excellent oxidative stability

- Very low moisture pickup

- Non-flammable

- Cryogenic-safe

- Easy machinability—low dust

Related Content

-

Honda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

-

Molder Repairs Platen Holes with Threaded Inserts

Automotive molder ITW Deltar Fasteners found new life for the battered bolt holes on its machine platens with a solution that’s designed to last.

-

Plastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.