U.S. Molders Warming Up to All-Electric Blow Molding

When I set out to research a feature on “What Molders Think About All-Electric Blow Molding Machines,” I thought it would be no big deal to get interviews with a handful of shops.

When I set out to research a feature on “What Molders Think About All-Electric Blow Molding Machines,” I thought it would be no big deal to get interviews with a handful of shops.

I’d target, say, one customer apiece from Bekum America, Kautex Machines, and Milacron, which have been the major proponents of the technology in North America. After all, Plastics Technology magazine has been reporting steadily on new generations of all-electric shuttles and injection-blow presses since at least the K 2001 show in Germany.

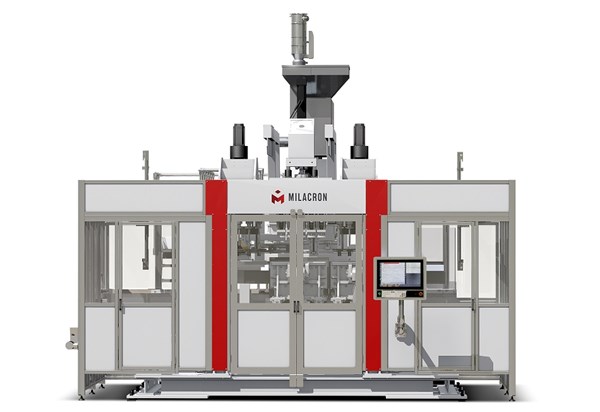

All three of those vendors (and probably more from Europe) are slated to bring out new all-electrics at the K 2016 show next month (see our September show preview). One of those new machines is Milacron’s M-Series (pictured), described in detail here.

Imagine my surprise, then, when I was given the name of exactly one U.S. molder to contact for this article, plus one in the U.K. and one in South Africa. It turns out that after 15 years on the market, all-electric shuttles and injection-blow presses amount to barely more than a half-dozen machines installed in North America.

The situation is very different in Europe, where all-electrics account for 80% of the shuttles Milacron sells. Bekum is selling a smaller but still significant fraction of its shuttle machines in all-electric versions, and Kautex has sells smaller shuttle models only in all-electric form. Milacron sources say they also have customers in Asia and South Africa that buy only electric machines.

While European bottle molders have jumped at the chance to cut their high electric utility bills, their U.S. counterparts are a more conservative lot and most of whom don’t pay as much for electricity. Even more, a lot of them have had plenty of available machine capacity and had resisted making major capital investments—at least until recently.

There are signs the tide may be turning. The number of all-electric machines on order now by U.S. customers appears roughly equal to the number installed—including the first electric injection-blow unit from Milacron. Kautex expects to see some bigger customers get into the act next year with 10 machine orders. Bekum is putting its hopes on its first electric shuttle equipped with U.S. components such as servo motors, actuators, and controls.

Blow molders looking for new machines should take careful note of the comments on all-electrics by the one U.S. bottle maker interviewed for my November story—and of the corroborating testimony from the South African molder. (The British molder did not respond to a request for an interview.) These molders know hydraulic presses well—and they’re sticking with all-electrics for the future.

Related Content

-

PolyJohn Turns to Blow Molding, Doubles Its Productivity

Leading maker of portable sanitation products knew thermoforming, sheet extrusion, rotomolding and injection molding. Then it found the missing link to higher productivity and new markets: blow molding.

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.