What You Should Know About Miniature Extrusion Screws

Very small screws have become more common with the growth of additive manufacturing. Designing such screws requires balancing their output requirements with their torque strength.

To accept pellets or even ground pellets, the feed sections of very small screws need to be proportionally deeper—that is, with a greater compression ratio—to match the output of the rest of the screw. That is due to the restrictive entry dimensions into the screw and lower compaction rates resulting from far fewer particles in the screw channel. Increasing the channel depth in the feed section naturally lowers the torque capacity of the screw.

In additive manufacturing equipment there has been a migration away from heat guns, which feed polymer filaments to supply the melted polymer, to miniature extruders. Miniature extruders increase part buildup rates or output and reduce material cost. Due to the poor heat transfer of polymers, the output of heat guns is limited, and the cost of filament is typically five times or more the cost per pound of pellets. Design of miniature or very small screws, whether used for additive manufacturing equipment or not, requires balancing their output requirements with their torque strength.

For additive manufacturing extruders, this may be even more important, as many are not operated by typical extrusion processors, and cold starts are inevitable. In such applications the screw strength needs to exceed the full torque available from the drive, so that during a possible cold start, where the drive torque instantly jumps to the full drive capacity, the screw does not break.

Compared with heat guns, miniature extruders increase part buildup rates or output and reduce material cost.

There are relatively simple calculations, using well established mechanical engineering principles, to avoid screw breakage.

The available torque from the drive is calculated as:

Drive torque (in.-lb) = (Horsepower × 63025) ÷ Maximum screw speed

For example, I recently worked on an extruder having a 2-hp drive motor with 1750-rpm maximum speed, coupled to a 10:1 gear reducer, resulting in a maximum screw speed of 175 rpm.

Available torque = (2.0 x 63025) ÷ (1750/10) = 720 in.-lb of torque.

The screw torque is calculated as:

Screw torque = 16T/(πd3)

Torsional strength equals 16 times the available torque from the drive divided by πd3 where (d) is the root diameter of the screw in its deepest section closest to the drive, which is the feed section. An example is a 0.625-in. diam. screw with a 0.325-in. root diameter in the feed section.

Torque strength = (16 × 720) ÷ (π × (0.325)3) = 106,820 psi

Torsional strength varies from zero at the center of a shaft to a maximum at its outer most surface. That’s why a screw-torque failure initially shows cracks initiating from the flight O.D. extending toward the center. There are different shape factors for determining the torsional strength of common shapes (squares, rounds, triangles, etc.). These have been experimentally developed, but none exist for the cross-section of a screw. As a result, the round section of the screw root is typically used, even though it represents less than the total torsional strength.

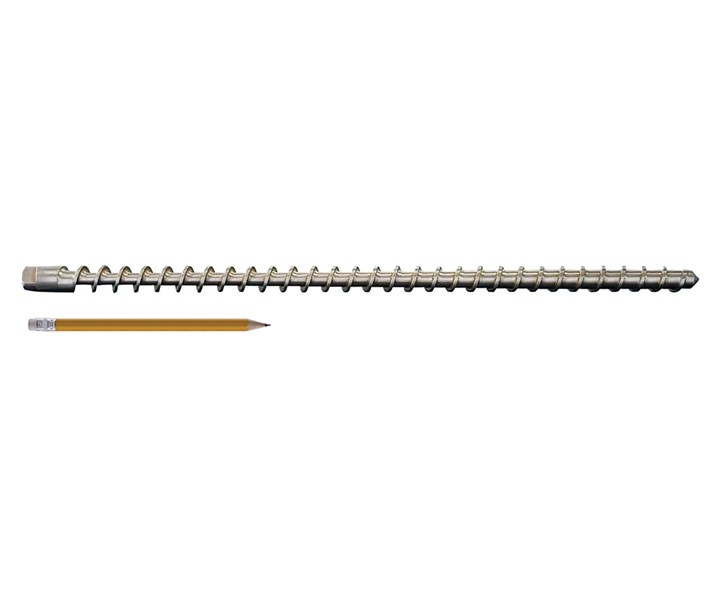

Tiny extruder screws (compared to pencil) figure to become more common as additive manufacturing expands. Shown here is a 5/8-in. diam. screw with an overall length of 16.28 in. Photo: Triex LLC-Filabot.

Tiny extruder screws (compared to pencil) figure to become more common as additive manufacturing expands. Shown here is a 5/8-in. diam. screw with an overall length of 16.28 in. Photo: Triex LLC-Filabot. Tensile strength of the typical steel for extrusion screws is 4140 steel heat-treated to 32 Rc hardness, which has a tensile strength of 145,000 psi. Shear strength for steels is conservatively specified as 0.577% of tensile strength, so allowable torsional stress is 83,655 psi, although the screw flight increases the strength an indeterminate amount.

That means that the feed section for the 5/8-in. screw noted above would be stressed to essentially 128% of maximum design strength at full drive load. To obtain the desired output, the depth of the screw would then have to be decreased and the maximum screw speed increased. Alternatively, a higher-strength steel such as H-13 could be used. At a hardness of Rc 52 its tensile strength is 289,000 psi and its torsional stress would be 166,753 psi or well above required strength. The H-13 tool steel was the solution chosen as the polymer was a copolyester with no corrosion issues.

About the Author: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724) 651-9196.

Related Content

NPE 2024: Additive Manufacturing Assisting, Advancing Plastics Processing

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

Read More420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

Read More3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More

.jpg;width=70;height=70;mode=crop)