Attending NPE2024 From the Perspective of a Molder

NPE2024 has come and gone, but before it’s completely in our collective rearview, Plastics Technology asked Rodney Davenport, vice president at injection molder CH3 Solutions, for a processor’s perspective on the big show.

Share

From left, CH3 Solutions at NPE2024: Rodney Davenport, VP; Lucas Edwards, supervisor; Jerry Wilson, maintenance manager; and Dave Salomone, production manager. At the show, a Wintec press molded the company’s Swisstrax modular flooring tiles from reclaimed ocean waste. Source: CH3 Solutions

When I arrived in Orlando, I was eager to witness the latest advances in technology and materials for our industry, as my fellow molders and I walked through the doors of NPE2024. There were so many innovative machines and innovative materials on display throughout the exhibition halls, it made you feel like you were walking into a futuristic world.

The precision and efficiency of robots in production processes were displayed, while the eco-friendliness of sustainable materials was highlighted. Industry experts in their respective booths exchanged ideas on how these advances could revolutionize plastic molding practices, while also networking with colleagues.

I was immersed in a sea of possibilities that promised increased productivity and reduced environmental impact. The types of innovation demonstrated were seemingly unending, pushing boundaries and reshaping the future of plastic manufacturing. I experienced firsthand how technology and materials are evolving to meet the market’s ever-changing demands at NPE2024.

Getting a Pulse on Plastics Innovation

One of the reasons I attended NPE this year was to gain insight into emerging trends and market demands. The plastic molding industry is constantly changing, with innovative technologies and materials influencing the way products are made. I saw attending NPE as a means to make sure I was not left behind.

A major trend in the industry and for my own company is sustainability. As consumers become increasingly aware of environmental concerns around plastics, there is a greater demand for eco-friendly materials and recycling of those materials. Visiting the NPE2024’s Sustainability Hub provided valuable insights into the process of transforming plastic waste into new products through recycling.

The types of innovation demonstrated were seemingly unending, pushing boundaries and reshaping the future of plastic manufacturing.

My attendance at NPE2024 offered the opportunity to examine sustainable options and for my company, CH3 Solutions, to partner with Engel. At its booth, a Wintec press was molding my company’s Swisstrax modular flooring tiles in real time at the show using recycled materials reclaimed from ocean pollution.

A crucial factor in the industry’s development is incorporating robotics into manufacturing procedures. Automation enhances efficiency and accuracy in plastic molding processes. Familiarizing oneself with the potential of robots to advance production capabilities can benefit molders seeking to streamline their operations. As the labor shortage persists, witnessing the various applications and integration methods of robots has provided me with numerous insights on enhancing my own manufacturing floor.

Reconnecting

Obviously, networking at NPE is a major part of attending the show. Six years since the 2018 show, I personally was eager to reconnect with fellow molders. At the end of an almost overwhelming first day, the opening night party was a terrific way to relax, wind down and have some much-needed fun with fellow industry friends.

It was also important for me to make new connections at NPE. Building relationships in the plastics industry is beneficial and can always lead to new opportunities. This was very evident by visiting the Manufacturers Association for Plastics Processors (MAPP) pavilion for its Wednesday night reception and seeing all the support from its members and sponsors lined up together in one aisle in the Advanced Manufacturing zone.

As I headed home from Orlando, here were my top show takeaways:

- Recycling/Sustainability are here to stay. Improving how we manage plastic waste is essential to the plastics industry’s survival.

- The use of automation to reduce waste and improve production capabilities is essential.

- With Industry 4.0 and the advent of artificial intelligence and virtual training, the future is looking very promising.

- The people in the plastics industry care about how our industry is perceived, and we are working together to make our processes more efficient, environmentally friendly and sustainable for the future of the next generation of plastics professionals. NPE2024 was an opportunity to display that commitment.

About the Author: Rodney Davenport is vice president at CH3 Solutions, an injection molding company in Dalton, Ga. He has more than 30 years of experience in the industry. Davenport grew up in Michigan, moved to Florida and started his career in injection molding there. Rising through the ranks through hard work and a helpful attitude, his passion for technology helped propel him further as he learned new processes and technologies throughout his career. In April 2015, Davenport helped establish CH3 Solutions as a brand new injection molding company.

Related Content

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreIs There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

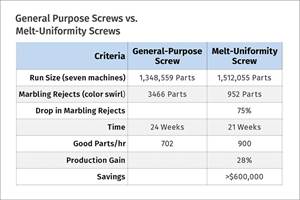

Read MoreImprove Production Rates Via Screw Design — Barrier vs. General Purpose vs. Melt Uniformity

I’m looking for a few good molders to help trial a new screw design, and share data and results for a future article to prove the benefits of a melt uniformity screw.

Read MoreProcess Monitoring or Production Monitoring—Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

Read MoreRead Next

Injection Molder Bases Company Culture on Employee Empowerment

After more than two decades in the industry, Rodney Davenport was given the opportunity to create an injection molding operation in his own vision, and — in keeping with the product he was making — to do so from the ground up.

Read MoreThe Cost of High Employee Turnover in Injection Molding: Why Retention Matters

Starting in molding in 1993 and clocking in for nearly every job on the floor over the intervening decades, I’ve seen all sides of the hiring, training and retention process in the industry. Here are my thoughts on how to keep your most important asset — your people.

Read MoreHeat-Activated Purging Concentrate Designed for Toughest Applications

Asahi Kasei Asaclean America’s Plus Grade blends seamlessly with a processor’s own production resins

Read More