Dynamic Tool Corp. Wins MoldMaking Technology’s 2024 Leadtime Leader Award

Dynamic Tool Corp., a provider of engineered tooling solutions based in Menomonee, Wisconsin, has been awarded MoldMaking Technology’s prestigious 2024 Leadtime Leader Award. The announcement was made during a live awards ceremony at the Plastics Technology booth, where owners Steve and Ken Eberle accepted the award on behalf of their team.

Share

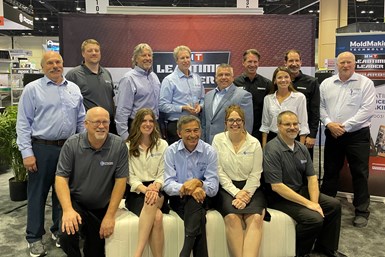

The Dynamic Tool team with MoldMaking Technology’s Christina Fuges and Leadtime Leader award sponsor Progressive Components

The Leadtime Leader Award, established in 2003, recognizes outstanding performance and innovation in mold manufacturing. It represents excellence in the entire mold manufacturing process, highlighting achievements beyond just short delivery times. Winners demonstrate a commitment to working smarter, using resources effectively and pursuing excellence with passion.

Glenn Starkey, president of Progressive Components and Award Sponsor since 2003, congratulated Dynamic Tool Corp. on their achievement, emphasizing the significance of this coveted award in the moldmaking industry. Ray Coombs, owner of the previous Leadtime Leader winner Westminster Tool of Plainfield, Connecticut, passed the torch with words of wisdom and congratulations to the new title holder.

Dynamic Tool Corp.’s success is attributed to their dedication to growth and core values of excellence, integrity, safety and customer focus. They are known for their innovative approach to quality, precision and efficiency, which has set them on a continual path to success.

Some highlights of Dynamic Tool Corp.’s achievements include:

- Repeat business from top custom molders and OEM brand owners, reflecting their commitment to on-time deliveries, exceptional customer service, engineering expertise and a dedicated workforce.

- Delivery of a 512-cavity stack mold in 2022 and a range of molds in 2023 spanning from one to 256 cavities.

- Specialization in high-performance parts with features like living hinges, threads, multiple materials, aesthetic requirements, inserted components and advanced mold capabilities.

- Significant investment in engineering resources, both personnel and technologies, to differentiate themselves in the injection mold builder market.

- Emphasis on craftsmanship in designing and building critical components in injection molds.

- Focus on team culture, collaboration, education through mentorship and self-motivation among employees.

- In-house design and integration of two automated machining cells and the use of a laser sintering and high-speed milling system to showcase technological capabilities.

- Integration of quality assurance into automated machining processes for immediate and practical metrology.

- Providing a complete experience, including service throughout the injection mold build, preventative maintenance and repair.

- Sales team consisting of engineers first and sales professionals second, playing a crucial role in delivering the proper customer experience.

- Commitment to sharing tailored educational content with customer engineering teams and promoting industry best practices for overall improvement.

Related Content

-

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.