Addex Continues to Advancing Cooling in Blown Film

NPE2024: Cooling specialist Addex debuts auto-profiling air ring for rotating dies, and new single-plenum air ring.

Share

For Addex, it’s all about blown film cooling, and this week they are debuting two new technologies in this area.

One is an auto-profile system for rotating dies, based on its high-resolution EGC (external gauge control) air ring. This unit, which is capable of reducing gauge variation by 50%, is already in operation on a single-layer line at a Crayex plant in Georgia, and at another undisclosed film processor in South Carolina.

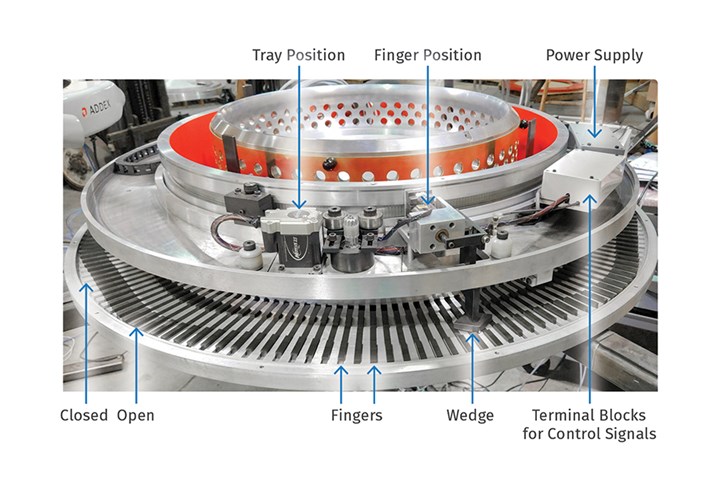

In the new air ring, air volume is controlled by a series of “fingers” that open or close to put more or less cooling air on the film, which thickens or thins the film out. On a 12-inch air ring, there are 168 control zones, with 200-plus control zones on larger systems. But the real key to this new technology is a proprietary mapping algorithm. When combined with Addex’s third-generation controller, software and hardware package, the system regulates not only the air ring but also the die rotation.

At NPE2024, Addex is unveiling the External Gauge Control air ring for blown film applications utilizing rotating dies. A 12-inch air ring will have as many as 168 control zones. “Fingers” open or close to direct more or less cooling air to specific locations on the bubble as needed. Source: Addex

Explains Cree, “On lines with oscillating haul-offs, the film is turning at the top, creating a twist that most processors have heard about, but in this case the die is fixed. It’s easier to make proper adjustments if the die is stationary, but rotating dies add another dimension to the auto-profile process that throws a huge monkey wrench into algorithm calculations.”

While rotating dies are perceived by some as passé, the fact is there are many still in operation. So, two years ago, Addex began talking with blown film processors with rotating dies that needed to improve film quality but couldn’t justify investing in a brand-new line to do so. “We kept hearing from our customers that they needed more quality from the lines they had — that because of the quality push in the industry and the move toward sustainability, they needed to get better film without breaking the bank.

“One of my biggest customers has a lot of rotating dies, so we were motivated, and we dusted off all of our old notes to take a fresh look at the problem, and installed our first auto-profiling EGC air ring-only system on a rotating die line at the plant in South Carolina last March. And the feedback from them was that the quality improvement was dramatic.”

Addex, however, learned something significant on this first retrofit in South Carolina that it applied to the second, more recent system installation at Crayex in Georgia, which took place in December 2023. For the South Carolina film processor, Addex basically integrated the auto-profile air ring into the processor’s existing die rotator. But the modularity of its Gen3 control package enabled Addex to go a step further with Crayex. Now it is also taking control of the die movement in concert with the traditional mapping, and that is the system that was installed at Crayex.

Cree adds that the South Carolina processor has ordered two more air rings now with the third-generation control package. The first of these started up in March. In addition to the two units already in the field, Addex is beta testing the Gen3 EGC air ring systems at a total of four locations, tweaking the technology to enhance its performance with each startup.

New Single-Inlet Plenum

Addex is also debuting its first-ever air ring with a single-inlet

plenum design. While multi-inlet air rings have conventionally outperformed their single-inlet counterparts because they provide more uniform air distribution, Addex got input from film processors that running just one hose rather than the 4, 6, 8 or 10 that are typical of multiplenum designs would be beneficial.

Single-inlet air rings can be especially troublesome on lines without automatic thickness control. Cree says, “Automatic units can compensate for any gauge variations caused by erratic air-flow distribution, and you can actually see the required inlet-related compensating control effects in the system, so lacking automatic profile control can be a problem.”

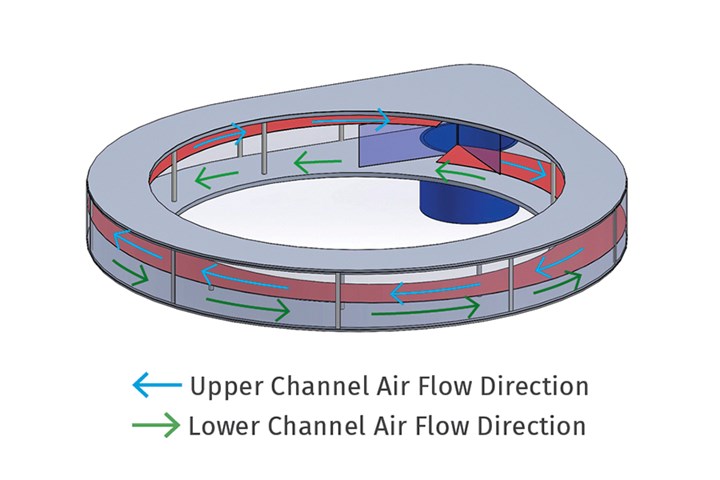

So Addex set a goal to design a single-inlet plenum that performed equal to what it had achieved with its multi-inlet conventional plenum. Its solution was to apply a regular division design inspired by Dutch artist M.C. Escher, in which irregular shapes, or combinations of shapes, interlock completely to cover a surface or plane. According to Cree, what Addex devised is a patent-pending, dual-counterflow plenum design with one circular channel flowing clockwise all around, and a second going in the opposite direction all the way around. This creates the Escher “equal and opposite” effect, resulting in uniform combined air flowing through the air ring.

Image shows the internal design of Addex’s new single-plenum design to more uniformly distribute air flow. Notice one circular channel flowing clockwise all around and a second going in the opposite direction all the way around. Source: Addex

At its pilot line in Newark, New York, Addex switched between the new single-inlet design and the multi-inlet unit, both without auto-gauge control, and notes the single-inlet plenum provided better overall thickness profile with reduced variability.

Related Content

Flexible-Film Processor Optimizes All-PE Food Packaging

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.

Read MoreMaterials Suppliers Team on PFAS-Free Solutions

Baerlocher PFAS-fee process aid passes muster in resin manufacturer’s testing on production-sized blown film line.

Read MoreFilm Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

Read MoreRoll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More