Updated Interactive Tool for Predicting Multilayer Film Performance

NPE 2024: NOVA Chemicals presents the latest enhancements to its Bonfire Multilayer Property Predictor and new Syndigo rPE portfolio

Share

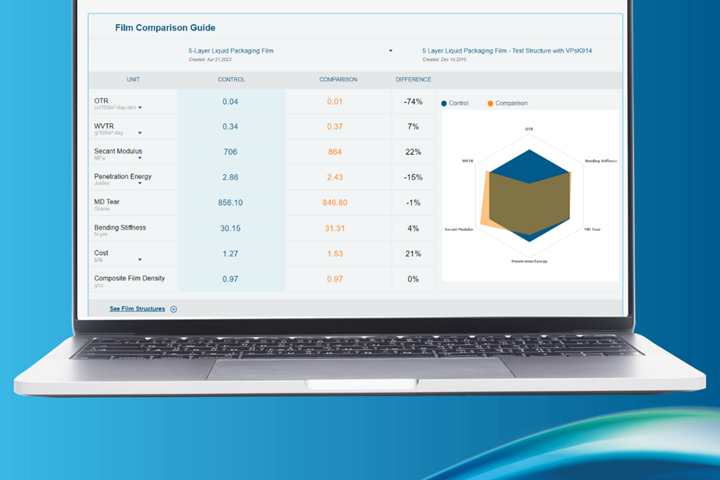

Further enhancements to the interactive web-based tool for predicting multilayer film performance developed by NOVA Chemicals are being presented to existing and perspective customers. With a wide range of tools at their fingertips, customers can find the most promising resins and structures that meet their requirements without the extensive physical trials that are typically needed during the design phase. The Bonfire Multilayer Property Predictor (MPP) also helps customers reach their sustainability goals by supporting downgauging and the incorporation of recycled polyethylene (rPE) to ensure their packages are designed for recyclability. The enhancements of Bonfire MPP 6.0 enable users to do the following:

- Film Comparison Guide — Compare predicted properties of similar films with different resins, blends or layer ratios.

- Coex Structure Builder — Assess the effects of additives on final film properties.

- Customization — Add a custom resin to a private database.

- Profitability Module — Enhanced features to access and compare the cost and profitability of different films and processing factors.

- Team Access — Add multiple users within a company to collaborate on structures, pricing, customizations and more.

NOVA is also presenting the latest on its Syndigo rPE portfolio including rPE-0860-FC, a 100% postconsumer rPE mechanically recycled resin sourced from natural HDPE milk, water and juice containers, which is said to be well suited for both rigid and flexible packaging. Possible applications include beverage caps, cereal films, barrier film and all PE stand-up pouches. Due to the robust mechanical recycling process, including sortation, washing and post-extrusion devolatization to eliminate odor, the result is a best-in-class resin.

Related Content

-

The Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

-

Part 3: The World of Molding Thermosets

Thermosets were the prevalent material in the early history of plastics, but were soon overtaken by thermoplastics in injection molding applications.

-

Lanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.