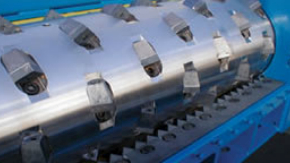

Shredders are for large or very dense parts. They can rip up large items into smaller pieces about 2” to 4” in size and are effective on a wide range of materials. Shredders reduce the time and effort required to manually cut up large parts. They can be used to efficiently reduce materials before going to the granulator.

Choosing a shredder depends upon the material to be cut as well as its size, shape and thickness. The amount of material that needs to be shredded and how the shredded material will be processed are also key considerations. The feed hopper must be evaluated for operator safety. It should be sized to receive the largest part being shredded without requiring labor-intensive and potentially dangerous precutting. Most safety devices in today's shredders involve electrical interlocks that prevent access to the cutting chamber until the rotor has stopped turning.