Aerosol Spray Cap is Recyclable

Dutch company Weener Plastics has developed a mono-material spray cap for easy recycling.

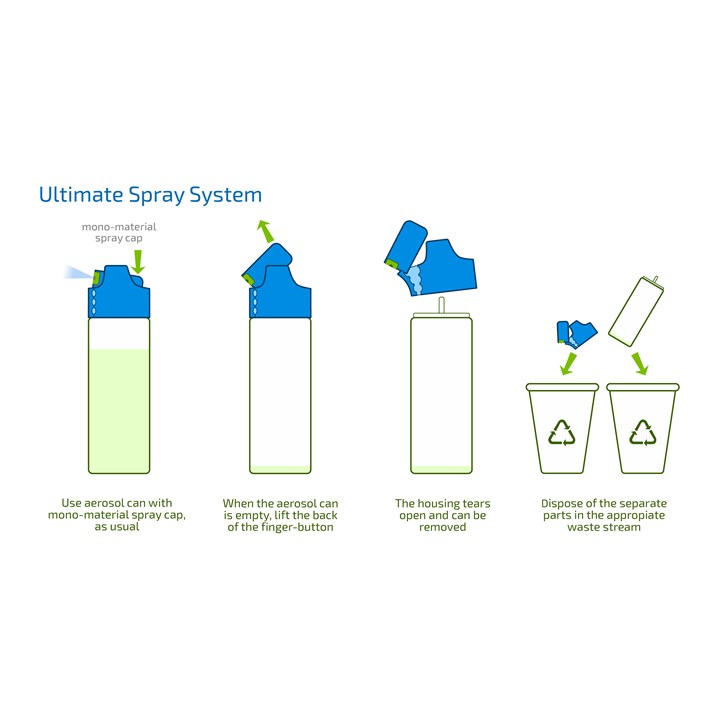

Weener Plastics has developed a fully recyclable aerosol spray cap, called the Ultimate Spray System, which consists of a two-piece spray cap made from a single material. According to Weener, the cap offers spray performance equal to proven, conventional spray caps.

Mono-material: PP Insert

To achieve refined spray patterns for specific application requirements, aerosol products often use a spray cap with an insert. Traditionally, inserts are made of PMMA, which cannot be recycled and disrupts waste streams. To address this, Weener makes both the insert and cap from PP, which can be recycled in standard waste streams. For true circularity, the cap is also available in recycled PP.

Removable Spray Cap

The PP spray cap can be easily and conveniently removed from the aerosol container before disposal. The finger-button can be lifted, at which point the housing of the spray cap is torn open and can be removed. The separate spray cap and aerosol container can then be disposed of in the appropriate waste stream.

Removal process of mono-material spray cap. Photo: Weener Plastics Group BV

Weener Plastics anticipates adoption of the spray system by customers involved in personal and home care products. Customers will be able to customize the spray characteristics including orifice and spray pattern. The caps fit standard aluminum and tinplate aerosol containers and can be processed on standard filling lines.

Related Content

-

Recycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

-

Gerdau Graphene Launches “First” Graphene-Enhanced PE Additive Masterbatch for Extruded Packaging and More

The company has also partnered with conglomerate Sumitomo Corp. for distribution of its graphene-enhanced masterbatches in Japan.

-

Evolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.