3D Laser Scanning Accelerated Production of PPE Masks for Coronavirus Pandemic

NVision’s non-contact scanning/measurement technologies have a growing role in helping to swiftly create products to minimize exposure to COVID-19.

There is a growing role for non-contact scanning/measurement technologies in the race to create new products and designs to minimize exposure to Covid-19. One excellent example from NVision Inc., Southlake, Texas, an industry acknowledged leader in 3D measurement and engineering services, is the engineering services it provided to a Texas PPE manufacturer, helping accelerate the company’s production of a much-needed protective mask earmarked for medical personnel. NVision engineers 3D-scanned plaster models of the mask, using the resulting data to create a computer-aided design (CAD) file which was used to build the special tooling necessary for production. NVision has assisted medical manufacturers in a wide variety of projects over the years, from measuring and inspecting surgical scalpels to reverse engineering heart stents and orthodontic braces.

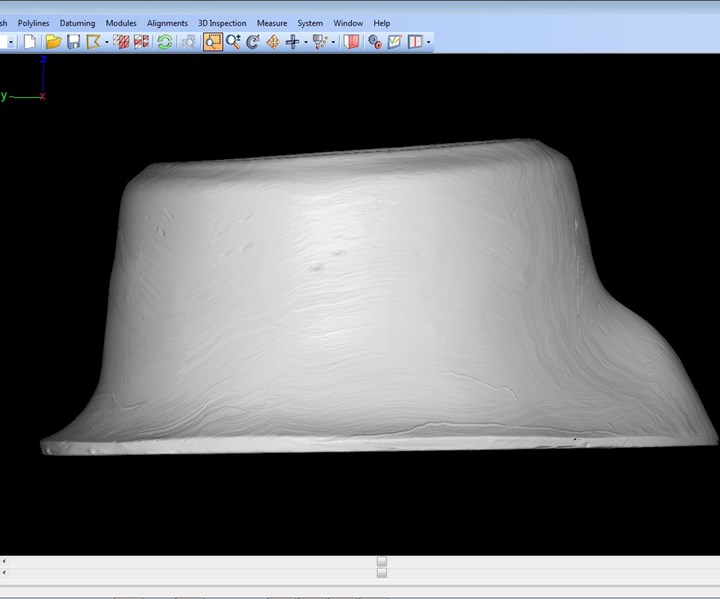

CAD rendering of thermoformed TPE mask.

The PPE manufacturer contacted NVision requesting a CAD model of a protective mask in three days in order to start creating the tooling for mass production. The company had only handmade plaster models of the mask; no previous computer models or designs existed. Said president of NVision Steve Kersen, “We had done work for this customer earlier on a Peterbilt Truck Project and they came to us with the mask project. The plaster molds for the mask had extremely challenging contours and to hand-measure its complex curvatures using calipers and other tools would have taken the manufacturer months, postponing production significantly.”

The mask is being made with a thermoplastic elastomer (TPE) thermoformed on wood molds. It consists of two parts--an inner and an outer part--with replaceable filter material. SolidWorks CAD models were required to facilitate the machining of suitable dies/molds, as the vacuum-forming process requires dies made from a more durable material, often wood or a metal. The mask is designed with a hole in the end with a filter, which will allow the user to breathe.

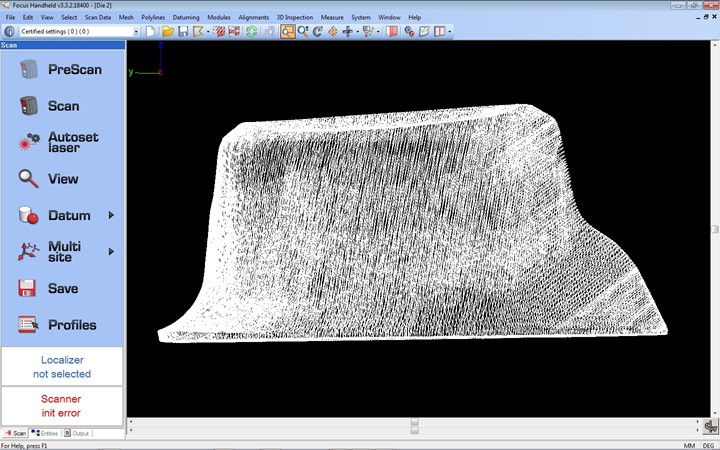

NVision profile of the “point cloud”

After receiving the plaster models, NVision technicians quickly set to work using NVision’s HandHeld laser scanner to collect data on the mask’s surface geometry and dimensions. This is a powerful portable scanning device capable of capturing 3D geometry from objects of almost any size or shape. The scanner is attached to a mechanical arm that moves about the object, allowing the user to capture data rapidly with a high degree of resolution and accuracy. As the object is inspected, the scanner generates a point cloud consisting of millions of points, each with x,y,z coordinates and i,j,k vectors. These points comprise an exact duplicate of the object’s surface, down to the most minute detail. The scanner comes with integrated software that is used to convert the point cloud to an STL polygon and an optional tripod provides complete portability in the field. Intuitive software allows real-time rendering, full model editing, polygon reduction, and data output to all standard 3D packages.

The scanning of the mask models took only two hours, after which NVision technicians converted the STL file to a native parametric SolidWorks CAD format from which tooling could be produced. NVision engineers provided the mask manufacturer with a CAD model from which it could build the tooling to begin production and meet its deadline for delivery of the masks. Said Kersen, “During the modeling process we were also able to make some changes that improved the mask’s design. We made it more symmetrical in shape and modified it to be more suitable for the manufacturing process.” “Without the fast and accurate measurements provided by laser scanning, the customer would have lost a great deal of time and money in performing manual measurements. With PPE, time to market is critical both for the health of those people waiting for masks as well as the business success of the manufacturers who need to reduce production time.”

Related Content

Krones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

Read MoreBaxter to Scale Up PVC Intravenous Bag Recycling Program

Successful pilot program with Northwestern Medicine will expand to additional units and health systems.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Read More3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More