3D-Printed Parts With Inherent Functionality Throughout

Patent-pending technology evenly disperses sensor particles in fused deposition modeling (FDM) filaments resulting in printed parts with inherent sensing capabilities.

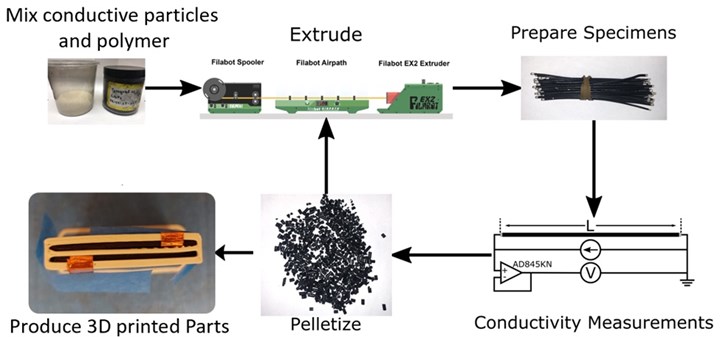

Purdue University (West Lafayette, Ind.) researchers have developed a patent-pending method to add sensing particles to fused deposition modeling (FDM) filaments and then disperse them evenly through a traditional 3D printing to create functional parts. To do so the researchers say they’ve created a novel wet-mixing method to introduce electrically conductive particles into 3D printing filaments.

The research team told Plastics Technology that they’re currently using carbon nanofibers (CNFs) for the conductive sensing particles with a thermoplastic polyurethane (TPU) as the carrier resin. The particles are uniformly distributed throughout and can be tunable, allowing the team to test various weight percentages. CNF fibers with a 100-nm diameter have been used, although the researchers say various sizes could be applied. At this point, post-dispersion lengths have not yet been measured.

In general, the researchers found that the minimum amount of sensor particles necessary to achieve functionality has been 5% by weight. “That is one unique aspect of this work,” a research spokesperson said, “we can fine tune the electrical and mechanical properties of the material to match final device needs.” In terms of the level of conductivity achieved, the researchers generally report resistivity of 16.44 Ohm-cm for 10 wt%, with the number varying depending on the weight percent.

In a release describing the research, Purdue noted that traditional foil-type strain gauges, which are the most common strain sensors, are presently adhered to the surface of a printed part by an epoxy resin. Using this technology, the sensing capabilities become an inherent part of the printed component, allowing sensing inside of the component. Too small to be seen without a microscope, the sensor particles’ tiny scale allows the printed part to maintain strength it would have otherwise sacrificed if larger sensors were built in. The long-term strength of printed components is often a limiting factor in applying the technology for production components, but with the ability to know what’s happening inside the part over time, the researchers say this development opens up more opportunities for additive manufacturing.

The wet-mixing process is not limited only to sensor conductivity and could include the addition of magnetic particles for electromagnetic fields, fluorescent particles and other functionalities.

Since the patents are pending, the researchers declined to discuss specific details around the intellectual property, but they noted that the patent will cover the materials, processes and overall functionality and uses of this produced material.

The research team includes Brittany Newell and Jose M. Garcia-Bravo, associate professors in the School of Engineering Technology in the Purdue Polytechnic Institute, and Tyler Tallman, assistant professor in the School of Aeronautics and Astronautics in the College of Engineering, who created the wet-mixing method to introduce electrically conductive particles into 3D printing filament polymers. Cole Maynard, who earned his PhD in August, and Julio Hernandez, a doctoral candidate, were also key to the research, according to Purdue.

Purdue researchers have created a patent-pending process to add functional additives to additive manufacturing filaments, allowing parts with functionality throughout.

Photo Credit: Purdue University

Related Content

-

NPE 2024: Additive Manufacturing Assisting, Advancing Plastics Processing

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

-

Business Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.