Bekum Acquires Thermoplastic Pultrusion Machinery Business

Blow molding machine builder Bekum buys into a very different field of technology with technology and personnel from insolvent ProTec Polymer Processing GmbH.

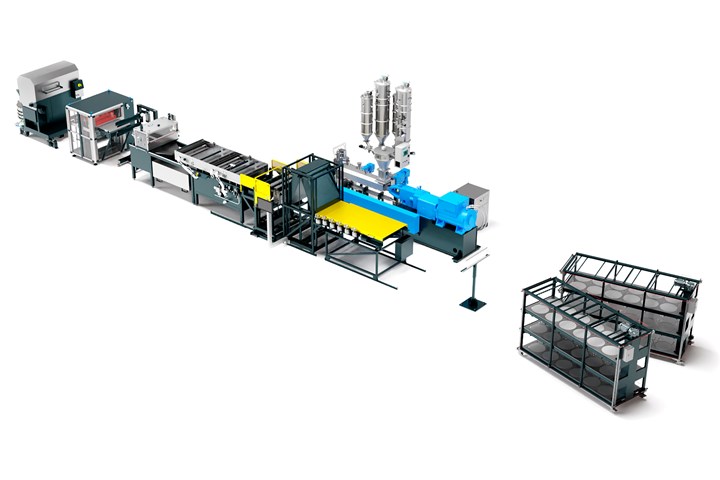

LFT pultrusion lines to make long-fiber thermoplastic pellets are a striking new diversification for blow molding specialist Bekum Maschinenfabriken. (Photo: Bekum)

Bekum Maschinenfabriken GmbH in Germany has acquired the long-fiber thermoplastic (LFT) pultrusion business of ProTec Polymer Processing GmbH, also in Germany. Bekum has retained the previous technical managing director of the insolvent ProTec company, along with experienced employees in design, sales and service. Bekum also purchased ProTec Polymer Processing Shanghai, which in recent years has sold LFT systems to the Chinese market.

With this diversification, Bekum – until now involved solely in blow molding machinery production – says it is “investing in a promising future market for fiber-reinforced plastics and is setting the course for further growth.” Bekum executives offered no further insight into this move, other than “It was a favorable opportunity and promises a developing future business branch.” Pultrusion, or strand drawing, is a method of producing long-fiber pellets that can be used to mold lightweight components for automotive and electromobility applications.

Assembly of LFT pultrusion lines has been integrated into the Bekum site in Traismauer, Germany, and the new business unit Bekum Services GmbH, headquartered in Bensheim, was created for the new division. Bekum will offer complete LFT pultrusion lines for processing eight, 32 and 64 continuous-fiber strands, along with installation and commissioning worldwide. Bekum will also continue to service existing lines in the market.

Not acquired by Bekum were ProTec SOMOS product lines in blending/dosing, drying, conveying and physical foaming, as well as PET post-condensation, and PET bottle-flake recycling.

Related Content

-

Injection Molded Tape and Resin “Sandwich” Technology Debuts

During its Mobility Days in Austria, Engel and KTM Technologies debuted an all-plastic molded motorcycle seat base produced via a tape-sandwich process that can run in a standard molding process.

-

Molder Repairs Platen Holes with Threaded Inserts

Automotive molder ITW Deltar Fasteners found new life for the battered bolt holes on its machine platens with a solution that’s designed to last.

-

Celanese to ‘Shine’ at CES 2023 with Expanded Portfolio of Materials

With it acquisition of DuPont’s engineering resins, Celanese’s resin solutions for automotive electrification, e-mobility and consumer electronics are plentiful.