Carbon Makes Design Engine Software Available to all 3D Printing Users

Previously, this software was available only to Carbon platform customers.

Carbon is launching the next generation of its Carbon Design Engine software and making the software licenses available to design teams globally for purchase in early 2022.

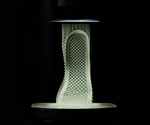

Carbon Design Engine allows product designers to generate advanced latticed parts quickly and easily from a solid part STL file and output STL files for printing on most common 3D printers. Previously, this software was available only to Carbon platform customers, but beginning in early 2022 software licenses will be available for individuals and teams to design, develop, and print advanced lattices on most common 3D printers. With this accessibility to Carbon's lattice-generating design software, design engineers and industrial designers can automate the process of creating conformal, multi-zone lattices.

Within Carbon's software suite, Design Engine automates complex product design and development from prototyping to production. Carbon says that innovative products designed with Design Engine have successfully moved from design to production in months and then been produced at scale.

"Creators are challenged with fragmented solutions and organizational silos that have caused friction, limitations on innovation, and delayed time to market. To successfully bring better products to market in less time, organizations need a platform that unifies product design, development, and manufacturing," said Phil DeSimone, chief product and business development officer at Carbon. "Carbon's software suite, starting with Design Engine, aims to cover every step needed for companies to create products with superior performance while accelerating the time to market."

Lattice structures require less material, while retaining tunable mechanical properties. As a result, latticed parts can provide performance advantages, including lightweighting, flexibility, improved cushioning and dampening, heat dissipation, and unique aesthetics. Because of Design Engine's ability to run complex computations in the cloud, design engineers can reportedly experience extremely fast design cycles to rapidly refine lattice designs in minutes, and use most 3D printers to manufacture them immediately. As a result, this tool can help creators go from idea to functional lattice part in hours, rather than days.

Design Engine has been widely used by global brands to design many products, including bike saddles, helmets, and sporting gloves.

Photo Credit: Carbon

Related Content

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

-

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

-

Additive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.