Collaboration Creates Recycling Loop for Multilayer PET

Water-based adhesive makes packaging film easier to delaminate.

The European Green Deal requires all packaging to be reusable or recyclable by 2030. The regulation is perceived as particularly challenging for multilayer packaging, since its layers first need to be separated before entering recycling streams.

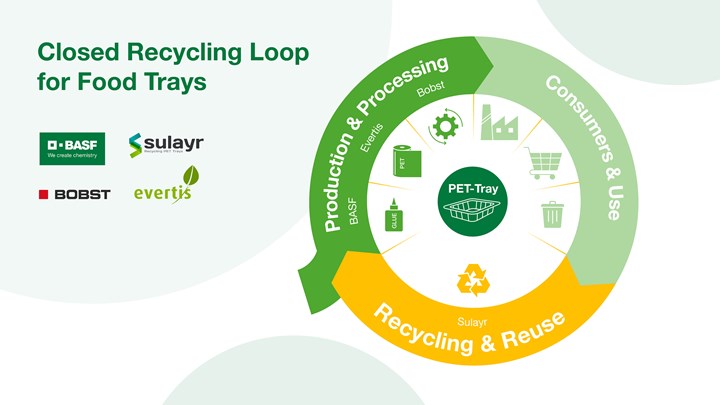

Collaboration throughout the value chain is required for circularity.Photo: BASF

A multilayer film produced by Evertis, comprising PET and PE layers, laminated with a BASF Epotal water-based adhesive and processed with a Bobst coating system, is produced for various applications, including thermo-formed food trays. After use, collected product can be used as a raw material by Sulayr. Sulayr has a process for separating the layers, recovering the PET for delivery to Evertis and other film producers. The process can be applied to both post-consumer and post-industrial product.

Sulayr has been able to separate multilayers since 2009, but the speed and cost-effectiveness depends on the debonding of the films. The new Epotal® water-based adhesive from BASF simplifies the process, enabling quicker and easier separation than is possible with solvent-based adhesives.

BASF has another new adhesive type currently under development, which promises to make the delamination process even easier under certain conditions.

Related Content

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

-

‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.