Henkel Working with Australian Company on 3D Printed Production Parts

Asiga has validated several materials for use on the MAX and PRO 4K series printers.

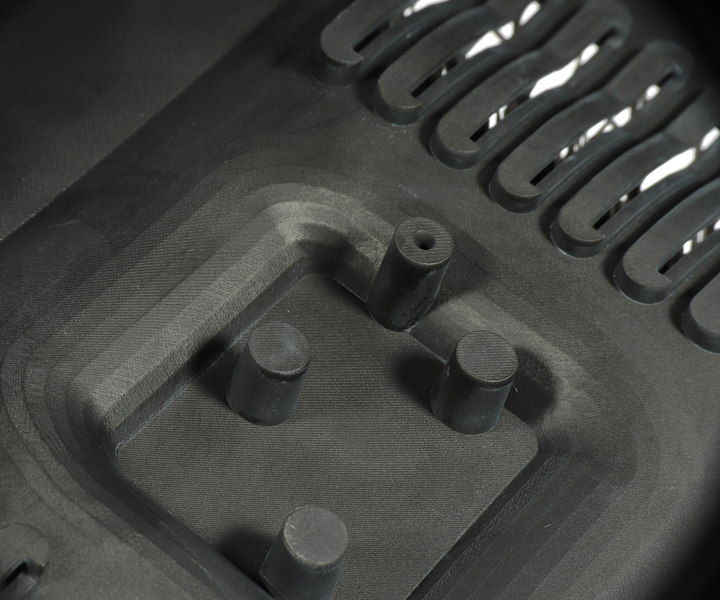

Detailed view of the 3D printed electronic housing part with ventilation slits and openings for cables and electronics.

Australian-based Asiga, a manufacturer of 3D printing equipment, has joined Henkel’s Open Materials Platform to provide the additive manufacturing industry with production-grade 3D printed parts.

Henkel offers a broad portfolio of materials for the 3D printing industry. Working together, the two companies are leveraging their experience in chemistry and 3D printing technologies to drive additive manufacturing production.

Asiga was an early user of desktop stereolithography, launching the world's first LED based DLP 3D printer in 2011. Today, the company continues to focus on a range of process monitoring technologies that control part accuracy and production stability across many industries including medical and general manufacturing. Asiga's product line consists of desktop 3D printers with their MAX series through to their large format floor standing PRO 4K.

Asiga’s SPS technology and Open Material System reportedly provides a repeatable, productive and accurate 3D printing platform for Henkel’s additive manufacturing materials. Asiga has validated several materials for use on the MAX and PRO 4K series printers.

“Asiga offers an innovative open platform that is cohesive with many of our materials,” says Sam Bail, head of OEM partnership, 3D printing at Henkel. “We also share a common vision of unlocking the promise of additive manufacturing at scale. The industrial sector is ripe for development, and with our combined solution, we are poised to help customers benefit from many of 3D printing’s biggest advantages, including design innovation, customization, speed, and scalability, among others.”

Related Content

-

DuPont Buys Medical Product Manufacturer Spectrum Plastics

Purchase price of $1.75 billion for leading supplier of extruded, molded, and 3D printed medical components.

-

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

-

Medical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.