Ineos Details Final Results of Polystyrene Recycling Project

Depolymerization helps to eliminate post-consumer waste and recover valuable resources.

Share

Read Next

Ineos Styrolution is reporting the final results of its polystyrene recycling research project. Called ResolVe, the project was granted a funding from the German Federal Ministry of Education and Research (BMBF) to explore the recycling of polystyrene. The company says that the project proves the feasibility of post-consumer waste becoming a valuable feedstock, which could create a circular economy for polystyrene. The project also included a commercial and an ecological evaluation of the recycling process.

The report concludes that depolymerization, a process that breaks polystyrene up into its building blocks, is an appropriate recycling solution for polystyrene in combination with distillation of the output for further polymerization. The process can produce recycled polystyrene that meet food contact standards.

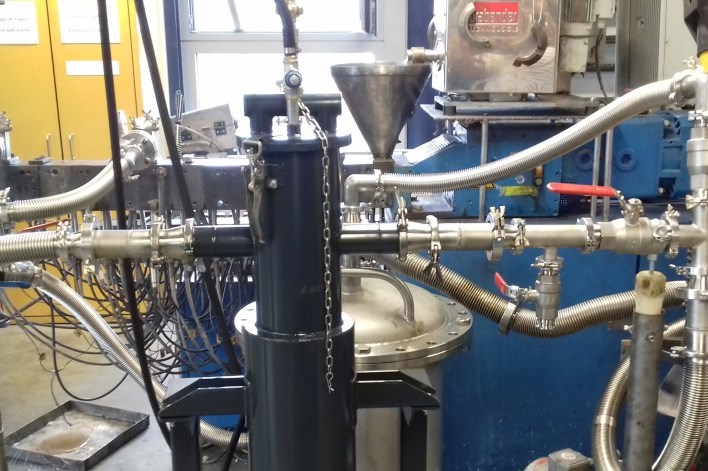

The research has shown that up to 75% of the output can be fed into the purification step and subsequently back into the production of new polystyrene. A key part of the project was the investigation of waste composition and the effect on styrene yield. This was done in a collaboration between the IKV (Institut für Kunststoffverarbeitung), the Institute for Processing and Recycling (Institut für Aufbereitung und Recycling, I.A.R.) and Neue Materialien Bayreuth GmbH (NMB). The most relevant process parameters temperature, mass flow rate, residence time and vacuum pressure, were systematically permutated and the best process conditions were identified. IKV Aachen transferred these basic process/properties relations to a larger scale and successfully de-polymerized polystyrene to styrene oil. As part of the research, the feasibility of additional processes including steamcracking of process residues were assessed, together with Ineos O&P as project partner.

The research has shown, however, that a stable depolymerization process is possible with a broad variety of feedstock material. Lightweight packaging and expanded polystyrene (EPS) waste have proven to be most suitable feedstock for the depolymerization process.

The depolymerization process not only contributes to the reduction of post-consumer waste and the recovery of valuable resources, a life cycle assessment of the production process for polystyrene revealed that the production with previously depolymerized material requires less energy and produces less CO2 than conventionally produced polystyrene.

ResolVe is a research and development project to explore the commercial use of post-consumer polystyrene waste as a raw material to produce high-quality plastics.

Related Content

-

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

-

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

-

Evolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.