Ineos Expands its Recycl-IN Product Line to Include More Recycled Content

The new product aims to address the critical problem of plastics waste and offer consumers more choice as demand for recyclability in packaging continues to rise.

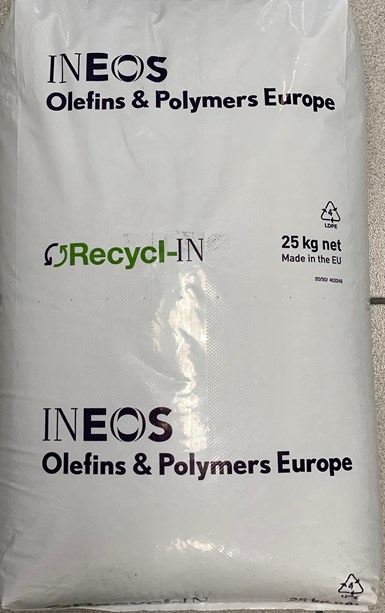

Ineos Olefins & Polymers announced it has partnered with waste management company Saica Natur in a supply agreement for recycled LDPE and LLDPE. The long-term agreement will help Ineos to serve the growing demand for increased levels of recycled product in sustainable, virgin quality flexible packaging.

Through this partnership, Ineos Olefins & Polymers has been able to develop high-performance polyethylene Recycl-IN resins to meet the needs of converters, brand owners and retailers, to use more than 60% recycled plastics in applications such as stretch and lamination films typically used in flexible pouches for detergent and personal care products.

Ineos O&P has expanded its Recyl-IN range of products to include packaging solutions with over 60% recycled content.

This new addition to the Recycl-IN range is for use in flexible packaging and pushes technical boundaries by incorporating more than 60% post-consumer recyclate (PCR). Recycl-IN combines the recycled plastic with highly engineered virgin polymers. The company says that the result has properties equivalent to virgin materials, while meeting the demand for an increase in the use of recycled materials.

“Together with Saica Natur, we have the innovation, drive, know-how and capability to move towards a circular economy for plastics in flexible packaging,” said Rob Ingram, CEO of Ineos Olefins & Polymers North Europe. “Saica are experts in recycling post-consumer plastic film. Ineos has the polymer science expertise to improve the quality, specification and performance of the finished product. We are pleased to add these new flexible packaging products to our Recycl-IN range.”

Related Content

-

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

-

Extrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

-

Coinjection Technology Showcases Recycled Material Containment

At Fakuma, an all-electric PXZ Multinject machine sandwiches a black core made of mechanically recycled PC/ABS within an outer layer made of chemically recycled ABS.