Printing From Pellet for Lower Cost, Higher Tensile Strength

Material qualification testing highlights advantages of skipping the filament in printing polyetherimide parts for aerospace applications.

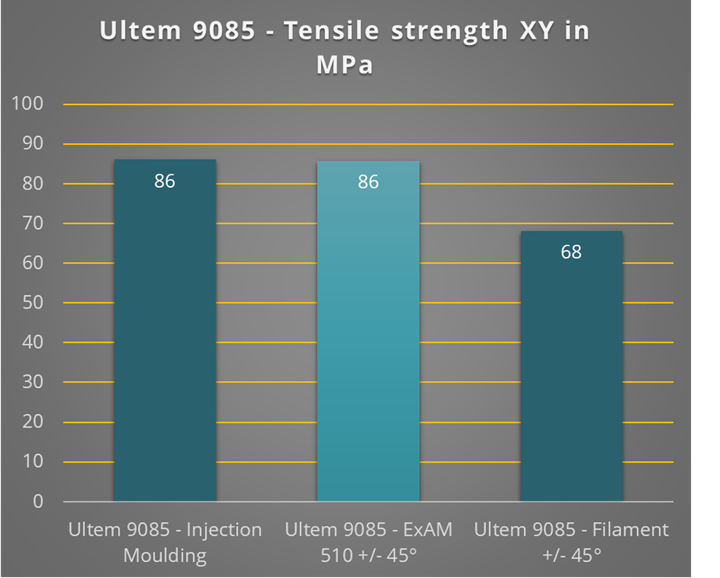

AIM3D released results of its material qualification testing of Sabic’s Ultem 9085, a polyetherimide (PEI), using 3D printing from pellet. AIM3D’s ExAM 510 printer uses the composite extrusion modeling process, which uses standard pellets rather that the filament required by other platforms.

A specimen is tested for tensile strength. Strengths in both the XY and XZ directions were higher when specimens were produced from pellets. Photo Credit: AIM3D Gmbh

The ability to print directly from a pellet is expected to provide a cost savings of up to 7 times compared with filament-based additive manufacturing. Results from AIM3D’s testing indicate that tensile strength is higher than achieved with filament printing and much closer to injection-molded parts from the same material. Standard deviations in the data were described as low, indicating that the process has high stability. Elongation at break was also higher for the pellet-printed material compared with filament printed.

Test results showed specimens were stronger when produced from pellet and comparable to those produced by injection molding. Photo Credit: AIM3D Gmbh

AIM3D also describes increases in build speeds with its process (up to 250 cubic cm per hour), reduced energy use, and shorter time-to-market. Sabic’s Ultem PEI is suited for aerospace applications, with low flammability and high strength-to-weight ratio.

Related Content

-

Additive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).