R&D Agreement Seeks to Advance Additive Manufacturing in Tooling

AddUp and Oak Ridge National Laboratory announced a $2.7 million cooperative R&D deal to advance laser powder bed fusion (LPBF) technology in toolmaking, including for conformal cooling.

AddUp, a supplier of full production lines for metal 3D printing, including powder management and printing machinery, is teaming with the U.S. Dept. of Energy’s Oak Ridge National Laboratory (ORNL) to research laser powder-bed fusion (LPBF) technology for molds and complex geometries, including conformal cooling.

A spokesperson told Plastics Technology that the $2.7 million cooperative R&D deal seeks to assess available materials and ease the introduction of new AM metals for tooling. “The end goal would be to not only perform a review and market analysis of tool steels in AM but also streamline the AM process and materials development for tooling, including in-process sensing challengers with respect to the complexity of handling volumetric data, indexing, and analysis,” the spokesperson said. “This would make the technology more suitable for a high-volume, production environment.”

Specific milestones the partners have achieved thus far include:

- Benchmarking and optimizing part density and microstructural characteristics of maraging steel under standard process conditions using metallography and μCT imaging.

- Characterizing microstructure and mechanical properties, including tensile strength and hardness, to determine ideal heat treatments.

- Building tooling inserts to achieve mechanical properties similar to conventionally processed tools.

- Building a tool for molding discontinuous fiber composites in collaboration with the MDF composites team.

The spokesperson said the research cooperative is open for industry collaborations to advance metal additive manufacturing for tooling applications and to test the results of the research in real production environments. “We invite industry partners interested in metal AM tooling applications and research and testing opportunities to contact us about being involved with this project.” At present, the cooperative was unable to share any OEM collaborations in development.

With regards to conformal cooling, the collaborative is seeking to deliver a technology capable of improving pre-existing processes of manufacturing conformally cooled molds, in addition to optimizing their mechanical properties, productivity and quality for enhanced performance in high-volume production environments.

ORNL will contribute an understanding of material properties and process parameters, including leveraging in-situ data analytics and advanced machine learning tools. By applying the latest characterization methods, ORNL hopes to speed up the delivery of validated AM process recipes and better understand the microstructural properties of AM tool steels.

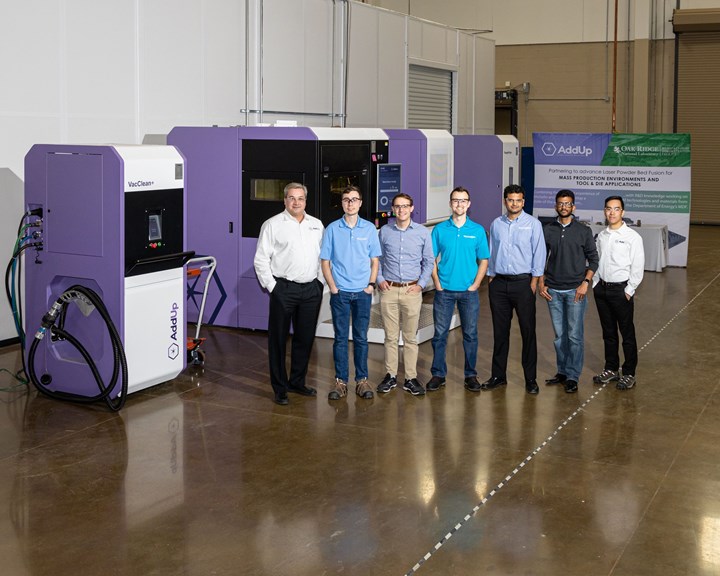

Oak Ridge National Laboratories and AddUp will be collaborating on the advancement of materials processes for metal additive manufacturing tooling applications.

Related Content

-

Make Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

-

Production Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.