Software Offers Three New Capabilities for 3D Printing

Scheduling, production monitoring, checking parts’ economic suitability for AM, and simulation that predicts part distortion—all specifically for additive manufacturing.

Three new software products offer MES capabilities, process simulation, and economic feasibility analysis for additive manufacturing (AM), also called 3D printing:

• Agile Manufacturing Execution System is an MES (manufacturing execution system) product designed specifically for AM. It automatically recommends production schedules in direct integration with parts orders. Using delivery dates and production specs, the system classifies parts for jobs based on production priority and machine availability. It comes from 3YourMind in Germany (U.S. office in San Francisco; 3yourmind.com).

• Another new product from 3YourMind is AM Part Identifier software that automatically checks a parts economic potential for 3D printing. AMPI searches large databases of existing AM parts to detect whether a new design is technically and economically suitable for AM based on material selection, quality and production requirements, and/or CAD specifications.

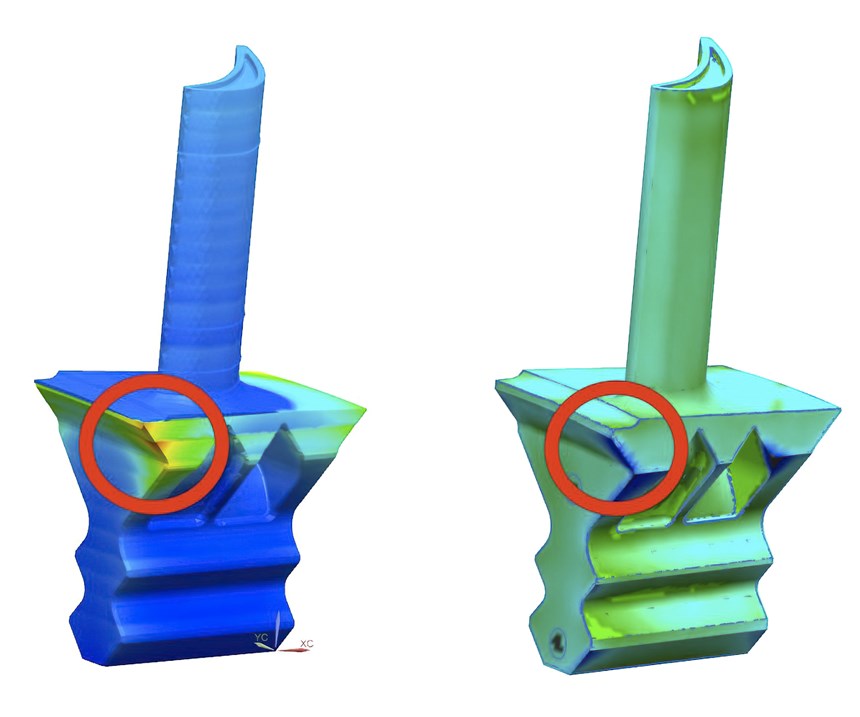

• New Simcenter 3D AM Process Simulation from Siemens PLM Software (U.S.office in Alameda, Calif.; plm.automation.siemens.com) helps predict distortion and shrinkage during 3D printing of metals and helps avoid these issues by automatically generating a compensated CAD model. The new program is fully integrated within Siemens’ NX CAD software and is based on the powder-bed fusion process for metal printing.

Related Content

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

-

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

-

Freeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.