Tooling Tech Supplied Thermoform Tooling for Hospital Bed Production in Support of Coronavirus Relief

Tooling Tech was able to go from design to finished tool in less that the two-week delivery requested by Kruger for Emergency & Disaster Relief Beds in the fight against the coronavirus epidemic.

In just another example of manufacturers rapidly stepping up to do their part in the battle against COVID-19, Tooling Tech Group (TTG), Macomb, Mich., recently announced that it has provided the thermoform toolsets for Emergency & Disaster Relief Beds being manufactured by Kruger Family Industries (KFI) brands TriEnda and Penda, Portage, Wisc. Deemed a Critical Infrastructure Company, Tooling Tech Group typically partners with the automotive and aerospace industries. Like many companies, it is currently working with several customers who are focused on manufacturing essential products for the medical industry.

TTG has been a long-time supplier to KFI, a major North American custom thermoformer which typically serves the automotive community. In this effort, TTG manufactured and delivered the bed base and backrest molds within 10 days—a quick response that is allowing the two companies to quickly move toward their goal of producing 3,000 beds per day at the Penda facility near Madison, Wisc. The 300,000 sq. ft. facility has been retooled for this project.

The tooling was provided by TTG’s Tooling Technology division located in Ft. Loramie, Ohio that specializes in thermoform, compression, and automation systems. By pulling together its resources and leveraging its vertical integration, the company was able to go from design to finished tool in less than the customer-requested two-week delivery. In addition to the original tool set, TTG has produced three additional bed base tools and two more back rest tools for thermoforming the beds.

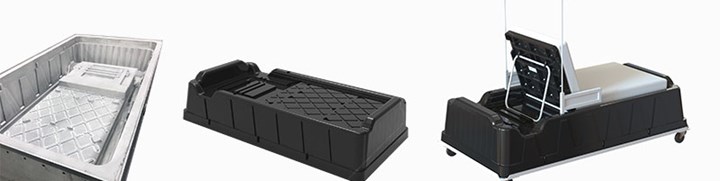

These new Emergency & Disaster Relief Beds are lightweight, made of durable 0.350” thermoformed HDPE material, and can be assembled on-site without tools in just a few minutes. A key feature of the bed is their ability to be stacked together efficiently for storage. The nesting allows for a reduction in storage space and quick redeployment in future emergencies.

Said Gary Poeppelman, president of TTG Compression & Thermoforming, “We are honored that TriEnda put their trust in TTG’s capabilities and happy that we could contribute to a project of such current significance. I also commend our employees for going above and beyond to produce this tooling so quickly, reducing the typical five or six week delivery time to 10 days while still addressing other customer needs.”

Related Content

-

Catheter Specialist Finds Sweet Spot Serving Small, Medium-Sized Concerns

Medical-component specialist LightningCath has carved a niche meeting the needs of small to medium-sized entrepreneurs with complex catheter designs … quickly.

-

DuPont Buys Medical Product Manufacturer Spectrum Plastics

Purchase price of $1.75 billion for leading supplier of extruded, molded, and 3D printed medical components.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.