Trexel Broadens Support for Foam Blow Molding

Agreement with MuCell Extrusion allows Trexel to pursue foam blow molding in packaging as well as automotive.

MuCell Extrusion, LLC has now granted Trexel, Inc. rights to offer MuCell microcellular foaming technology to the entire extrusion blow molding market. Trexel has long offered foaming solutions for automotive blow molding of products such as ducts, but until now it was restricted from pursuing extrusion blow molding applications beyond automotive according to a non-competition agreement that was part of Trexel’s sale of its extrusion business to Zotefoams plc, the parent company of MuCell Extrusion.

Automotive ducts blow molded with MuCell microcellular foaming technology were exhibited by Trexel at the K 2019 show. (Photo: Plastics Technology)

Notes Trexel CEO Brian Bechard, as Trexel has sharpened its focus on injection molded packaging in recent years, it has seen a pull from the market to offer its MuCell solutions for blow molded packaging, too. Whereas MuCell Extrusion also developed some foam blow molding applications, it is refocusing on extruded sheet and film, according to David Sterling, group CEO of Zotefoams.

Related Content

-

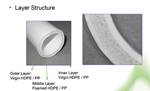

Injection Molded Tape and Resin “Sandwich” Technology Debuts

During its Mobility Days in Austria, Engel and KTM Technologies debuted an all-plastic molded motorcycle seat base produced via a tape-sandwich process that can run in a standard molding process.

-

PEEK for Monolayer E-Motor Magnet Wire Insulation

Solvay’s KetaSpire KT-857 PEEK extrusion compound eliminates adhesion and sustainability constraints of conventional PEEK or enamel insulation processes.

-

Honda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.