VOID Opens R&D and Compound Manufacturing Facility for Sustainable Flexible Packaging

This marks the materials science company’s first plastic reduction research labs and compound manufacturing facility

Materials science company VOID Technologies has opened its first plastic reduction research labs and compound manufacturing facility to help packaging manufacturers and brand owners transition to more sustainable plastics and packaging. The new multi-million-dollar facility in Neenah, Wisconsin offers R&D services and toll compounding for customers interested in developing flexible PE packaging based on VOID’s patented VO+ technology.

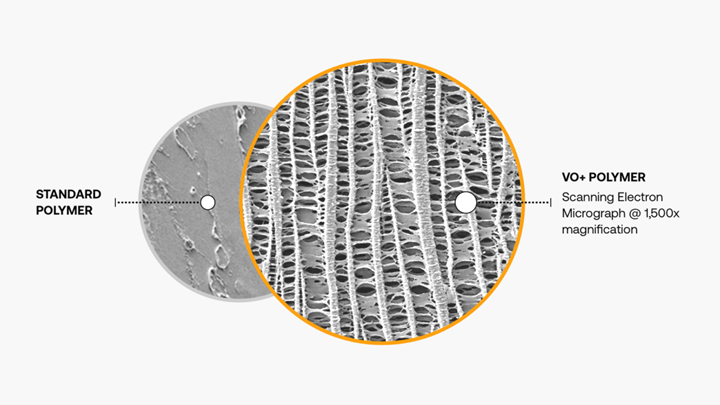

VO+ technology engineers nano- and micro-scale air pockets into plastics to create high-performance products with a lower environmental impact. It reportedly is effective in a range of thermoplastics including polyolefins and polyesters. Currently, the technology is most developed in white machine direction orientation (MDO) PE films. The company notes that by combining the benefits of MDO with VO+ cavitation technology, products can achieve:

▪ Material reduction: Lower density and downgauging

▪ Enhanced performance: Improved puncture, toughness, and high opacity without TiO2

▪ Improved recycling: VO+ white films turn clear during recycling because they are free of pigments like TiO2

With the official opening of the site, VOID has launched VOID Labs, whereby packaging and consumer goods companies can access the company’s start-of-the-art equipment. That includes pilot-scale blown film extrusion with inline MDO, lab- and commercial-scale twin screw compounding, as well as a range of testing and analytical equipment.

VOID is already working with leading companies along the supply chain to develop VO+ MDO PE films for a range of applications such as laminates, wicketed bags and frozen food. The company expects initial product launches in the second half of 2022.

VOID’s extensively patented VO+ technology was first conceived as part of a research initiative at Kimberly-Clark. Not long after, in 2015, VOID was launched as an independent company. Today, in addition to its R&D labs and compound manufacturing facility in Wisconsin, VOID has R&D has commercial teams in Canada, France, and the UK.

Related Content

-

Recycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

Purpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.