Products

Interactive Training for Injection, Extrusion and Other Processes

Paulson has four in-booth stations demonstrating its various training solutions.

Read More'Groundbreaking' Flame Retardant PC and PC/ABS

Trinseo’s new FR PC and PC/ABS produced without PFAs or halogenated additives

Read MoreMachine Series Debuts for Chen Hsong

NPE2024: Chen Hsong has three injection molding machines in its booth, including 2-platen, hybrid and a next-generation line with improved platen and toggle design.

Read MorePEK for Metal Replacement and Applications Requiring the Highest Heat Resistance

NPE 2024: Polyplastics’ new Sarpek polyetherketone (PEK) is said to be an advancement over PEEK.

Read MoreNext-Generation All-Electric and Vertical Injection Molding Machines

Sodick Plustech’s VR-G and MS-G2 Series both utilize the company’s proprietary V-Line technology, separating plasticizing and injection functions, and have upgraded displays, energy efficiency, response time and more.

Read MorePrecise Blender for Low-Throughput Molders

NPE2024: Gravimetric batch blender precisely delivers precise material blends from up to four ingredients at extremely low throughputs.

Read MoreDownstream Line for High-Precision Profiles

NPE2024: System features calibration and cooling tables, haul-offs, cutting units and tilting tables.

Read MoreSmart Granulator Control Integrates Size-Reduction Systems, Enables Predictive and Knife Maintenance

NPE 2024: Conair’s New SG Control is available for its Viper Granulators

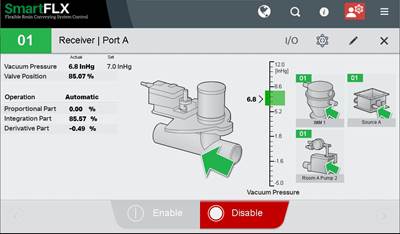

Read MoreArtificial Intelligence Manages Changing Conveying Conditions

NPE2024: Billed as an industry first, controls autonomously adjusts the conveying system in real-time to move material under optimal conditions.

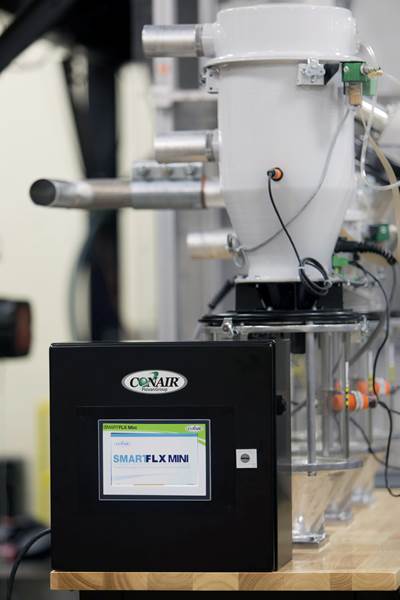

Read MoreMini Control Offers Central Conveying for Small Plants, Work Cells

NPE2024: System supports vacuum conveying systems with up to three vacuum pumps and a maximum of up to 12 receivers.

Read MoreAI Manages Resin Drying Airflows and Throughputs for Energy Savings

NPE2024: Optional feature automates the process of maintaining process-ready resins at perfect temperatures and varied throughputs, while preventing overdrying and realizing significant energy savings.

Read MoreResin Drying Hoppers Offer More Energy Efficiency, Durability and Cleanability

NPE2024: Drying hoppers provide improved energy efficiency and a durable textured metal exterior finish. Thicker insulation provides a cooler working environment, while polished stainless steel interiors resist material entrapment, and make cleanouts and changeovers faster.

Read More