3D Printer Management Software With New Quality Assurance Functionality

Stratasys has announced new GrabCAD Print Pro software for the management of 3D printing preparation.

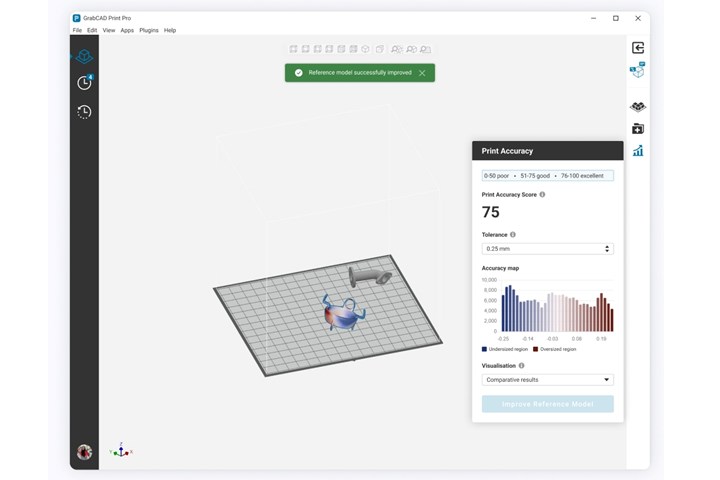

Stratasys announced the launch of its new GrabCAD Print Pro software, with integrated quality assurance functionality from Riven, acquired last fall by Stratasys.

GrabCAD Print Pro allows manufacturers to make necessary adjustments and can reduce material waste while speeding up the additive manufacturing process.

Graphic: Stratasys

GrabCAD print software manages the print preparation process for Stratasys 3D printer. The new Pro version is designed to improve printed part accuracy, reduce waste, and shorten time to part. It includes the features of Grabcad Print standared with additional features for better control, reduced production time, and enhanced workflows:

- Automatic warp correction to ensure part accuracy

- Ability to develop manufacturing templates

- Label generation

- 3D array to arrange parts on X axis, enabling stacking of parts

- Integration with partner plug-ins

Initial plug-in partners include AlphaSTAR and Castor. AlphaSTAR provides toolpath-driven analysis and quality assessment of print parameters, as well as thermal process simulation to help improve design cycles and produce higher quality parts with less iteration. Castor’s decision-support software automatically analyzes thousands of parts at once to identify the best opportunities for additive manufacturing.

The new software is expected to be available from May 16 for customers using Stratasys printers based on SAF and FDM technologies.

Related Content

-

Business Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

-

Additive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

-

Medical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.