Additive Manufacturing: New 3D Printing Materials for Antistatic, Low-Wear & Food-Contact Parts

New igus materials for SLS and FDM/FFF printing.

igus has introduced three new materials for 3D printing in its proprietary iglidur line.

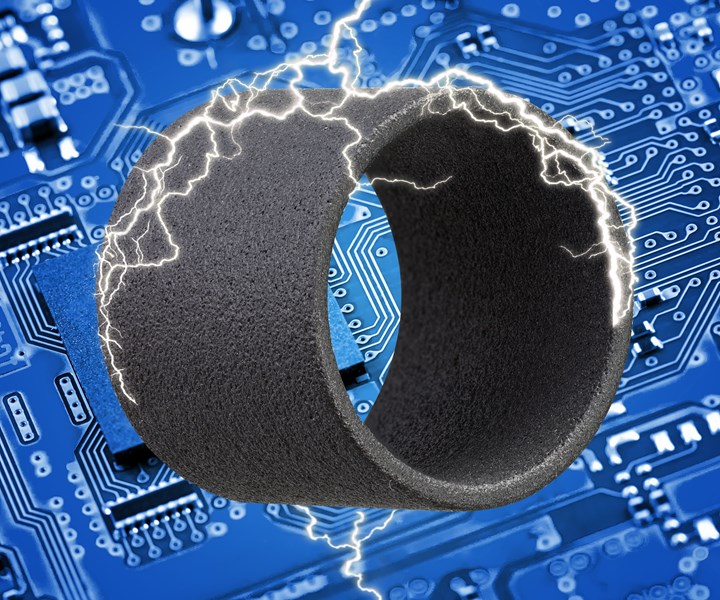

New igus iglidur powder for SLS has ESD properties plus high wear resistance.

• iglidur 18-ESD is a powder for SLS printing that combines good electrostatic dissipation (ESD) with high wear resistance. Aimed at electronics, it boasts static resistance of 3 × 107 ohm-cm and wear resistance twice that of nylon 12 SLS materials. Like all iglidur materials, it requires no additional lubrication. Also, it is inherently black, so no coloring is required.

• iglidur A350-PF is a new filament for FDM/FFF printing that combines FDA food-contact approval with high-temperature resistance—180 C/356 F long-term exposure limit and 210 C/410 F short-term limit.

• igidur I190PF is a new filament with high wear resistance and high strength. Containing solid lubricants, it boasts abrasion resistance 50 times that of ABS. Flexural strength is 80 MPa (11603 psi). Heat resistance is 90 C/194 F long-term, 110 C/230 F short-term.

• In addition, igus is now offering iglidur filaments in larger spools weighing 8 kg (17.6 lb).

Related Content

-

OCSiAl Opens First Large-Scale Graphene Nanotube Plant

The new facility in Serbia will serve Europe, North America and Asia to drive advances in plastics and rubbers.

-

High-Jetness Carbon Black for Engineered Plastics

Orion’s new Printex chroma 500 Beads are well suited for applications such as injection molded automotive parts and household appliances.

-

Plastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.