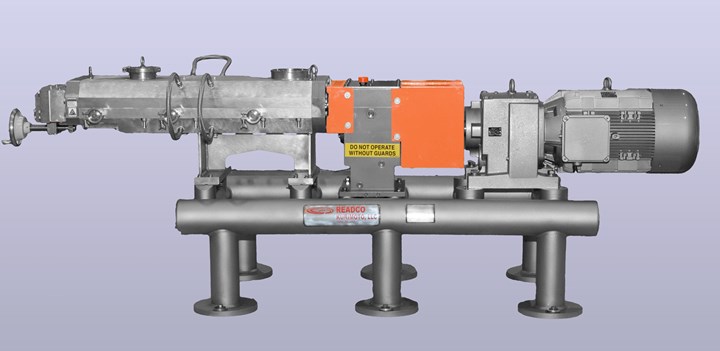

Compounding: Continuous Processor Can Run Safely on Empty

Proprietary power transmission design and bearing configuration make this possible.

Continuous Processors from Readco Kurimoto LLC, York, Pa., feature a proprietary power transmission design and bearing configuration that allow them to be operated safely while running on empty. Said to be an upgrade versus extruders that must rely on the material to guard against metal to metal contact with the barrel, the Readco units automatically prevent the mixing elements from contacting the barrel and eliminate risk of contamination from metal to metal contact to allow safe startup without any material in the process. By loading the recipe, raising the barrel temperature, and verifying the system settings while running empty, the Continuous Processor saves on both material and energy at every startup.

When shutting down for cleaning or maintenance, the units may be run on empty to allow the designed-in, self-wiping action of the mixing elements to automatically purge approximately 95% of the material from inside the mixing chamber. This Readco advantage minimizes the need for chemical cleaning agents, offering especially significant cost savings and environmental protections in systems requiring solvents for cleaning, the machine builder says.

Related Content

-

How to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

-

How to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

-

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.