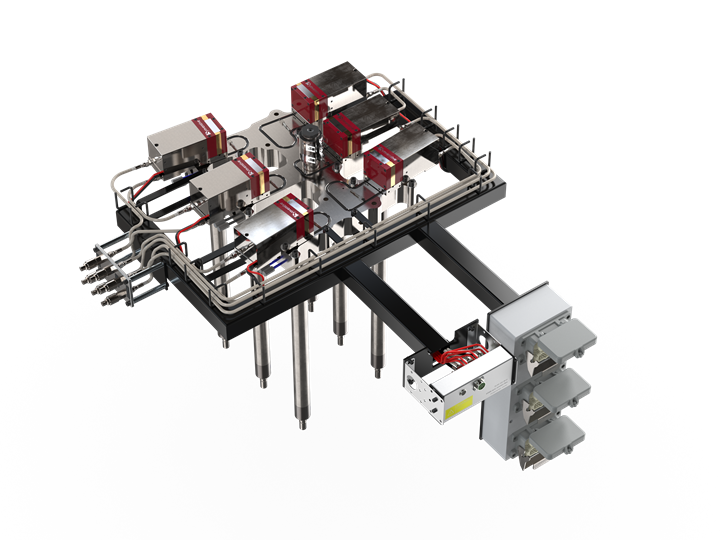

Electric Valve-Gate Technology Debuts

Synventive will use PTXPO to debut its eGate sync hot runner technology to the North American market after its global debut at last year’s Fakuma.

Positioning the system as cost effective and easy means to capture the benefits of electrically driven movements in a hot runner, Synventive is positioning the eGate as an alternative to molders looking to move away from hydraulic or pneumatic systems but not requiring the minute control capabilities of its traditional eGate product.

Allowing for the electrification of hot runners, Synventive’s eGate sync hot runner system can be added to an existing tool but replacing the actuator and adding the junction box and controller.

Photo Credit: Synventive

Saying the system uses up to 7 times less energy than a hydraulic power unite, the eGate sync consists of a small machine-mountable controller, an electric actuator, a junction box and a safety signal module. User interface comes in the form of an app pre-installed on a 10-inch tablet, with some basic control functions located on the controller box. Connections are simplified as well, with motor power and motor signal cables between the actuator and the junction box, which connects to the controller via a power cable and signal cable.

The eGate sync’s junction box can control up to 12 zone and store “recipes”, allowing molders to save process settings once a mold is dialed in.

Photo Credit: Synventive eGate sync

Related Content

-

Got Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

-

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.