Heating/Cooling: Advanced Mold-temperature Control at K 2019 Show

Larger electronic TCU and automatic mold blow-out function debut from Engel.

Engel showed two enhancements of its program to digitalize mold-temperature control at October’s K 2019 show in Düsseldorf. One exhibit was the new e-temp XL model, a larger version of its TCU with variable-speed pump, built for Engel by HB-Therm of Switzerland. The new unit has pump capacity up to 32 kW, double the previous maximum size.

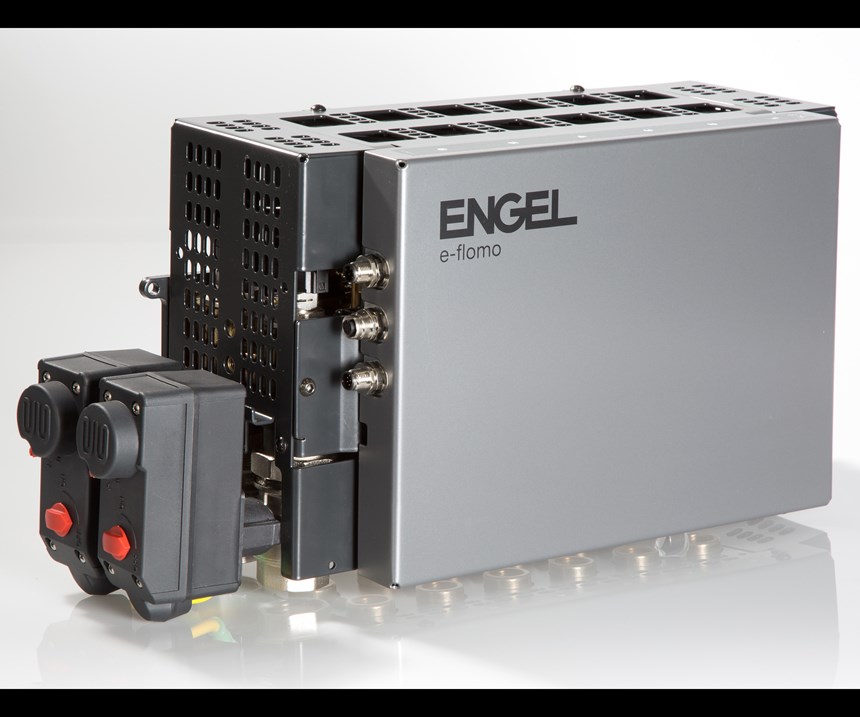

The e-temp TCUs can be integrated with an Engel injection machine’s CC300 control via Engel’s iQ flow control software, which dynamically regulates the volume flow rate to match the process conditions. To make this possible, another key element of the system is Engel’s e-flomo electronic water manifold (pictured), which can monitor and control flow and temperature in individual water channels. A new e-flomo feaure introduced at K 2019 is automated, sequential air-purging (blowing out) of the manifold circuits in the injection mold when changing molds or mold inserts. This is normally a manual process that is time-consuming and not always reliable, as compressed air often does not flow evenly through the circuits. The new optional feature for the premium version of e-flomo is said to speed mold setup and minimize the risk of residual water remaining in the cooling channels.

Related Content

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

ACS Group Adds Regional Sales Manager

Richard Gutierrez named Southwest regional sales manager.

-

Troubleshooting Leaky Temperature-Control Units

Learn the causes, symptoms and remedies for TCU leaks to keep these vital contributors to plastics processing up and running longer and more efficiently.