High-Efficiency Stabilizer for Aliphatic Nylons

Brüggemann’s Bruggolen TP-H1804 designed for use at continuous temperatures between 320°F-to-374°F

A new heat stabilizer masterbatch for aliphatic nylons is said to provide longer service life at high temperatures. Bruggolen TP-H1804 from Brüggemann is designed for use at continuous service temperatures between 320°F and 374°F. It complements Bruggolen TP-H1805 which stabilizes reinforced nylons at temperatures above 392°F. Supplied in granular form, this additive concentrate can be dosed very precisely, and thus in a very targeted manner.

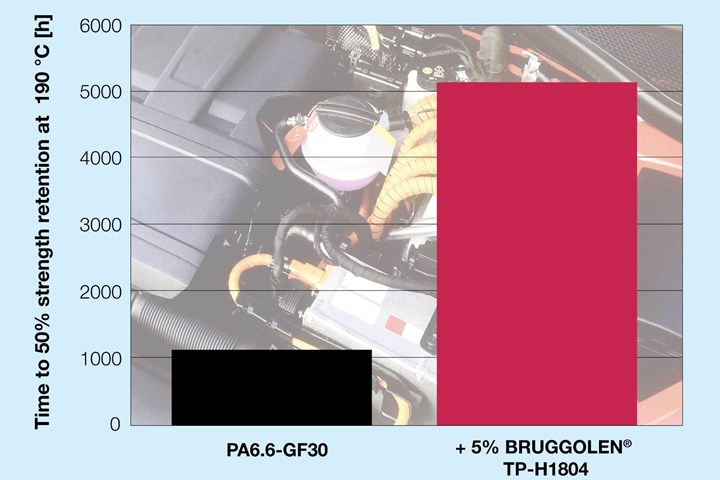

As “best in class”, according to the company, Bruggolen TP-H1804 significantly outperforms previously available copper salt-based stabilizers in terms of maintaining mechanical properties. For example, the tensile strength of a glass fiber reinforced nylon 66 with the addition of 5% is still over 50% of the initial value after 5,000 hours of heat ageing at 374°F; the un-stabilized material barely reaches this limit at 1,000 hours. At 338°F, thanks to its outstanding efficiency, even 2.4% is sufficient to exceed the 5,000-hour mark. As such, Bruggolen TP-H1804 is a product which, through its flexible dosing capability, allows molded component service life to be adapted to expected thermal loads.

Related Content

-

Soft Prices for Volume Resins

While PP and PE prices may be bottoming out, a downward trajectory was likely for all other volume resins, including engineering types.

-

The Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

-

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.