High-Speed, Form-Cut-Stack Thermoformers, Robotic Trim Press Handle, Next-Generation Controls

BMG to showcase GN915 thermoformer as well as new Mantis robotic trim press handler and next-generation controls at K 2022.

New thermoforming equipment from Brown Machine Group (BMG) to be featured at K 2022 in Dusseldorf this October, include products from GN, Brown, Lyle, Freeman, and NAS under the BMG branding. Spotlighted products will include:

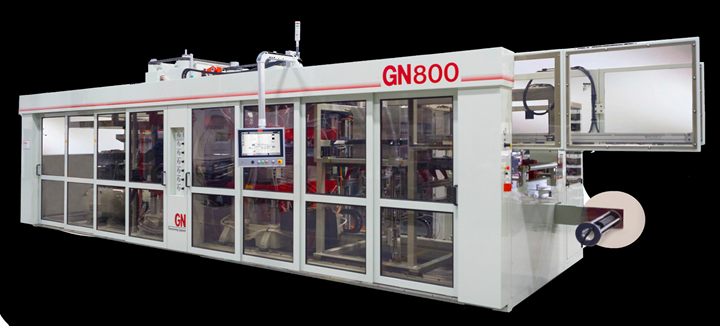

▪ GN800 and GN915: GN’s flagship GN800 and the new GN915 are high-speed, plug-assist, form-cut-stack thermoformers. This reportedly innovative equipment uses fully-integrated servo controls throughout–including the movable top and bottom platens for precise forming and cutting of parts. With multiple configurations and forming areas, easy to use HMI, and the ability use competitor tooling, the GN thermoformers are said to be an ideal choice for food, medical or consumer packaged goods project.

▪ NAS Mantis Robotic Trim Press Handling System: The Mantis robotic trim press handling system is the next generation in thermoformed product handling. Compatible with all trim presses but specifically designed for both non-servo- and long-eject models, it is said to be ideal for handling lids, cups, bowls, and clamshells, Mantis reportedly can automate counting and separation of parts from any trim press machine and can reduce users labor requirements by up to 75% at the end of the trim press.

▪ BMG’s NextGen Controls: This is reportedly an intuitive, easy-to-use HMI platform that simplifies operations and reduces training requirements for new employees. Compatible with most existing servo-based BMG machines, the NextGen Controls platform will provide a common look and feel to all BMG brands and future products.

Related Content

-

Cobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

-

OMV Technologies Gets New CEO

Kooper brings 33 years of experience in the industrial and consumer packaging industries to OMV--the closed-loop, turnkey, inline extrusion, thermoforming and tooling systems manufacturer.

-

Winners Announced for SPE Thermoforming 2023 Parts Competition

More than 30 entries were considered, including 10 in the Sustainability category.