Injection Molding: Servo-Hydraulic Line of Toggle-Style Machines Headed Stateside

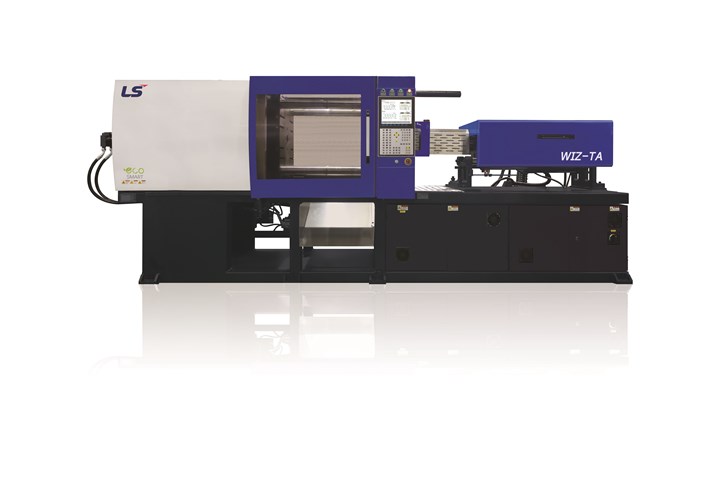

Korea’s LS Mtron will be offering its WIZ-TA series of servo-hydraulic toggle injection molding machines in the U.S. with clamp forces ranging from 55 to 420 tons.

LS Mtron is adding the Korean-built WIZ-TA series of servo-hydraulic toggle injection molding machines to its U.S. offerings. Ranging from 55 to 420 tons of clamping force, LS MTron says the WIZ-TA series will complement its existing offerings to the U.S. market, which currently include all-electric machines from 20 to 950 tons and a 2-platen servo hydraulic range going from 550 to 5000 tons.

Targeting general-purpose customers, LS Mtron positions the WIZ-TA as a cost-effective option to an all-electric machine, while reportedly still providing 70 percent of the energy savings an all-electric would offer.

Thanks to U.S.A.-Korea Free Trade agreement, LS Mtron points out that there are no import duties or tariffs on the imported machines and quick delivery is available thanks to plans to stock more than 25 units of various sizes in the U.S. LS Mtron formally re-launched its brand in the U.S. at NPE 2018. Since that time, the company says more than 130 units have been sold into North America.

LS Mtron’s WIZ-TA series of servo-hydraulic toggle presses is coming to the U.S.

Related Content

-

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

-

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.