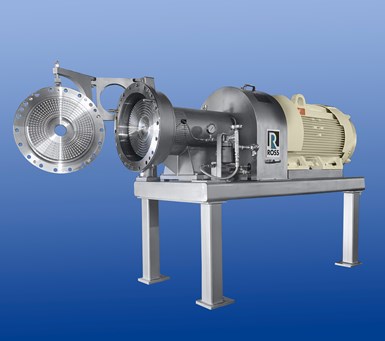

Inline Ultra High Shear Mixer

Designed to deliver exceptional dispersion, emulsification, and homogenization at high throughput.

Ross’ Inline Ultra High Shear Sanitary Mixer Model HSM-715XSUHD-250 is designed to deliver exceptional dispersion, emulsification, and homogenization at high throughput. Featuring the patented X-Series rotor/stator in type AL-6XN stainless steel, this mixer takes product through the center of the stator and moves it outward through radial channels in the rows of concentric rotor/stator teeth. The combination of high tip speed and extremely close tolerances between the interlocking channels subjects the product to intense shear in every pass.

Designed for continuous operation the HSM-715XSUHD-250 is driven by a 250 hp washdown duty inverter-duty motor and equipped with heavy-duty tapered roller bearings. Its mixing chamber can withstand 150 psig at 250°F and features a stainless steel jacket for heating/cooling. This model is CIP compliant, with the back of the mixing chamber relieved to promote very thorough cleaning around the seal area.

Photo: ROSS

With its ability to produce top-quality dispersions, suspensions and emulsions with uniform size distributions, this versatile and easy to clean mixer is ideal for various industries such as food, cosmetics, pharmaceuticals, chemicals, adhesives, and composites manufacturing.

The HSM-715XSUHD-250 is supplied with a NEMA 12 pre-engineered control panel.

Related Content

-

Safety, Recycling, and Compounding Trends Bring New Opportunity to 70-Year-Old Company

NPE2024: Vac-U-Max presents pneumatic conveying solutions for powdered materials.

-

Configuring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

-

How to Maintain Pelletizing Quality When Acid Attacks

Developments in the chemistry of polymers and additives have made corrosion a real problem in pelletizers. Here’s how to ward it off.