Keeping The Heat on The Barrel

Noncontact radiant heaters embedded in ceramic-fiber insulation save energy and keep heat from being lost into the plant environment.

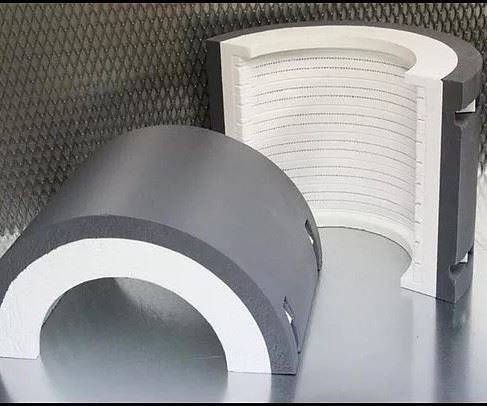

Exposed heater bands represent wasted money. (You may be relying on them to heat your plant in winter, but that’s an inefficient way to do it.) Rex Materials has a solution in its patented TCS (Thermal Control Solution) radiant heaters, which replace conventional heater bands and direct the heat into the melt, rather than into the surrounding air. TCS consists of radiant heaters embedded in segments of ceramic fiber insulation. Unlike heater bands, these heaters do not depend on direct contact with the barrel—in fact, they don’t touch the barrel at all.

The TCS is said to reduce energy costs by 40% on average, with the potential to pay for itself in 16-24 months. What’s more, time to heat up the barrel from a cold start is cut in half, the company says.

Related Content

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

-

Using Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

-

Got Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.