Materials: Single-Layer Flexible Graphite for Consumer Electronics

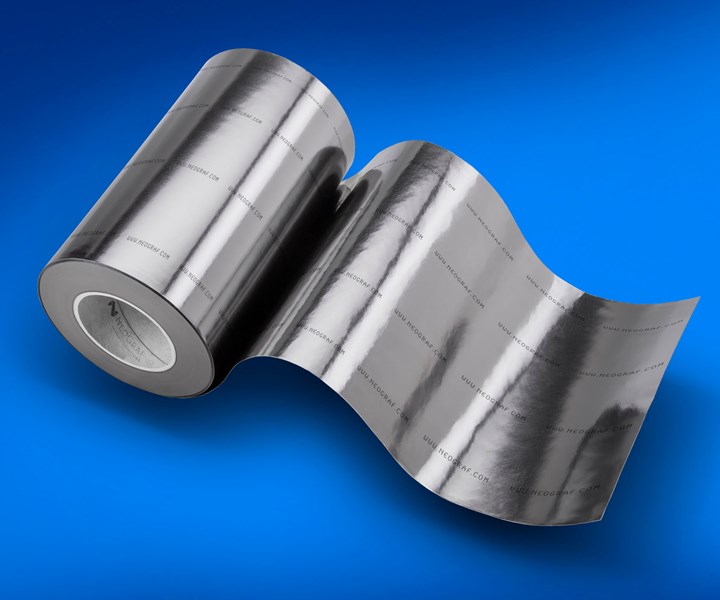

NeoGraf Solutions’ NeoNxGen single-layer graphite sheet poised as next-generation thermal management technology for high-end electronics.

A family of high-performance, thick, single layer flexible graphite solutions reportedly eliminate the cost, complexity, and reliability concerns of multi-layer systems used in consumer electronics. NeoNxGen Thermal Management Solutions was recently launched by NeoGraf Solutions, Lakewood, Ohio, a leading developer and manufacturer of high-performance natural and synthetic graphite sheets and powders.

NeoNxGen advanced flexible graphite heat spreaders have the high thermal conductivity of synthetic graphite yet are much thicker than traditional synthetic products. These next-generation thermal management solutions are primarily targeted for high-end consumer electronics such as notebook computers, mobile phones, and tablets.

Today, many modern electronics devices require multiple layers of synthetic graphite to function properly, according to NeoGraf product manager Jon Taylor. “These multiple layers are complicated to manufacture, expensive, and generate excessive scrap during the lamination process. NeoNxGen flexible graphite spreads a large amount of heat with a single layer yet is thin enough to fit in the limited allowable space of modern electronics.

NeoNxGen flexible graphite has the thermal conductivity of synthetic graphite (900W/mK to 1100 W/mK). It exhibits strong repeated flexibility characteristics, making it ideal for applications with foldable displays, or any other application where the product will be repeatedly flexed and bent.

NeoNxGen flexible graphite is designed to compete against multiple layers of synthetic graphite that have been laminated together into a stack. These multiple layers of synthetic graphite offer acceptable performance but the manufacturing process is a disadvantage. This product provides a high level of heat spreading using a single layer of graphite while the competition relies on the use of multiple layers of graphite to achieve the same level of heat spreading.

The company’s NeoNxGen P-150 grade offers comparable performance at a 15% reduced cost (at 150μm thickness) versus competitive multilayer solutions. NeoNxGen flexible graphite also delivers quality advantages including greater reliability (no adhesive layers), fewer splices (reduced downtime), and no additional inspection. The product portfolio includes the standard N-Series and the economical P-Series, while custom grades based on thickness and performance are available upon request. Several other new grades are under development to meet specific market needs. In addition to consumer electronics, NeoNxGen flexible graphite is ideal for demanding applications such as automotive electronics, battery thermal management, aerospace, military, and medical. To date, it has successfully found commercial use in laptop computers.

Related Content

-

Plastics Machinery Shipments Rose in 2022’s Final Quarter

The Plastics Industry Association’s (PLASTICS) Committee on Equipment Statistics (CES) reported that injection molding and extrusion machinery shipments totaled $432.7 million in Q4.

-

Flame-Retardant PP Compounds

Sirmax North America now offers a broad range of these compounds within three key product families

-

Plastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.