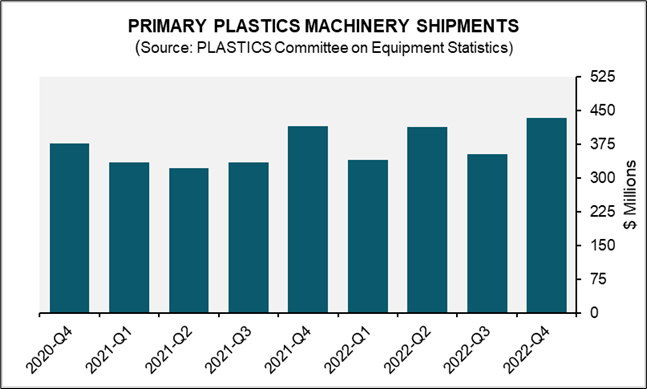

Plastics Machinery Shipments Rose in 2022’s Final Quarter

The Plastics Industry Association’s (PLASTICS) Committee on Equipment Statistics (CES) reported that injection molding and extrusion machinery shipments totaled $432.7 million in Q4.

The preliminary estimate of machinery shipments according to reporting companies totaled $432.7 million in the final quarter of 2022, marking a 22.3% increase over the previous quarter and a gain of 4.4% compared to the prior year. These findings come from the Plastics Industry Association’s (PLASTICS) Committee on Equipment Statistics (CES). Of the three primary type of plastics machinery, the value of single-screw extruders increased by most, rising 34.6%, followed by injection molding shipments, which grew by 25.0% compared to the third quarter. Shipments of twin-screw extruders rose by 8.9% compared to the third quarter. Compared to the fourth quarter last year, shipments of single and twin-screw extruders increased 7.6% and 25.0%, respectively. Injection molding shipments were 2.9% higher compared to the year earlier.

In its quarterly survey of plastics machinery suppliers, CES reported an an increase in the percentage of participants expecting market conditions in the next quarter to remain unchanged or to improve. Survey participants also expected to see market conditions over the next 12 months to remain unchanged or improve.

Plastics machinery exports grew by 10.2% to $198.8 million in the third quarter. Mexico and Canada remained the top export markets, as the combined exports to USMCA partners totaled $109.7 million. This represents 65.9% of total plastics machinery exports from the U.S.

Imports decreased by 12.1% to $423.6 million in the third quarter, which served to narrow the U.S. plastics machinery trade deficit from $260.7 million in the second quarter to $224.7 million in the third quarter. CES said this reflects the fact that moderating global economic growth and a strong U.S. dollar are slowing down plastics machinery trade.

Plastics machinery shipments were on the rise again in the final quarter of 2022.

Photo Credit: PLASTICS

Related Content

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

-

Use Cavity Pressure Measurement to Simplify GMP-Compliant Medical Molding

Cavity-pressure monitoring describes precisely what’s taking place inside the mold, providing a transparent view of the conditions under which a part is created and ensuring conformance with GMP and ISO 13485 in medical injection molding.

-

Consistent Shots for Consistent Shots

An integral supplier in the effort to fast-track COVID-19 vaccine deployment, Retractable Technologies turned to Arburg and its PressurePilot technology to help deliver more than 500 million syringes during the pandemic.