Materials: Ultra-High Flow ABS and ABS/PC Blends for Automotive and Appliances

Elix Polymers is now offering three new ABS and ABS/PC blends for achieving lightweight, thin-walled long parts due to their reported ultra-high flow properties.

At PT’s Molding 2019 conference, a presentation by Spain’s Elix Polymers (U.S. office in Weston, Fla.) unveiled three new very high- flow ABS and ABS/PC blends specifically formulated to achieving thin-walled and lightweight parts for both appliances and automotive.

▪ Elix ABS 118HF is a high-flow ABS formulated to reduce the overall part thickness of intricate parts, including long parts, as well as material costs and cycle times. Boasting excellent impact, strength and flowability properties along with a very high-gloss surface finish, it is said to be ideal for appliance housings, other consumer goods, and compounding where it can boost flowability.

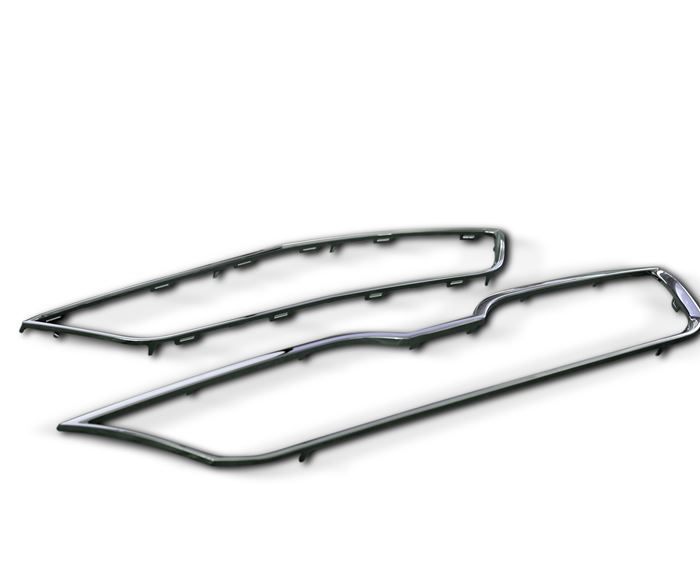

▪ Elix ABS/PC Ultra HH4115PG is designed for plating applications where very high technical requirements are needed. Included are both automotive interior and exterior parts such as decorative center control parts, door panel and handle parts, front grill frames, exterior trim, tailgate handles and emblems. The material boasts lower density and easier processability than PC/ABS grades with higher PC content. Its excellent dispersed rubber phase through grafting and particle size control reportedly ensures high-quality plating and metal adhesion. Adhesion thermal cycle and cross-cut test studies have been carried out on plated parts with successful results that fulfill OEM requirements.

▪ Elix ABS/PC Ultra HH4115HI is formulated for automotive exterior and interior applications with high-impact resistance requirements. It boasts several advantages over PC/ABS including a 5% lower density, a very high impact strength, as well as low emission and odor (VDA 278 VOC=8/FOG=3ppm). Moreover, its high-flow-rate has been shown to reduced cycle times. Puncture impact behavior tests carried out according to ISO 6603-2 confirm the excellent performance of this material at different temperatures for crash-relevant parts such as exterior pillars, as well as interior trim and parts subject to knee or head impacts. The appearance and structure of fractures produced in the test have been evaluated by several premium automotive OEMs. Significant cost savings are possible thanks to its better paintability vs. PC/ABS, which leads to reduced scrap rate. The company envisages a wide range of applications for the material, including door panel and instrument panel parts, center console and luggage compartment trim, seating parts and both interior and exterior pillar covers.

Related Content

-

Prices Bottom Out for Volume Resins?

Flat-to-down trajectory underway for fourth quarter for commodity resins.

-

The Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

-

What is the Allowable Moisture Content in Nylons? It Depends (Part 1)

A lot of the nylon that is processed is filled or reinforced, but the data sheets generally don’t account for this, making drying recommendations confusing. Here’s what you need to know.